ProductPRODUCT

Featured products

Contact Us

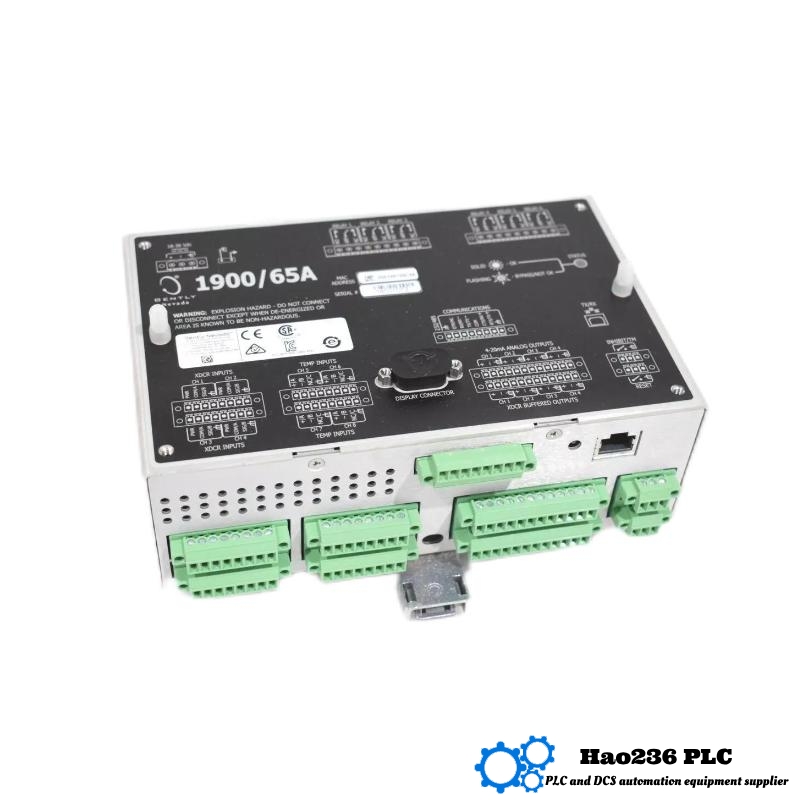

- Bently Nevada

- 1900/65A-00-00-01-00-00

- General Purpose Equipment Monitor

- USA

- 196.9 x 149.4 x 74.4mm

- 0.77 kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 11

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Bently Nevada 1900/65A-00-00-01-00-00 General Purpose Equipment Monitor

Product Introduction

The Bently Nevada 1900/65A-00-00-01-00-00 is a universal equipment monitoring system designed for industrial rotating machinery. It provides continuous, real-time monitoring and protection against equipment failure by detecting vibration, temperature, and other key parameters in critical assets.

This system is ideal for applications where a full-scale protection system like the 3500 Series is not required but where cost-effective, reliable monitoring is still essential. It is widely used in industries such as oil and gas, power generation, and manufacturing, helping to prevent unplanned downtime and costly repairs by identifying potential failures early.

Product Parameters

| Parameter | Specification |

|---|---|

| Dimensions (L x W x H) | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.77 kg |

| Power Supply | 100-240V AC / 24V DC |

| Number of Channels | 4 (configurable inputs) |

| Input Types | Accelerometer, Velocity, Proximity Probe, RTD, and Thermocouple |

| Frequency Range | 10 Hz – 10 kHz |

| Communication Interface | RS-485 Modbus RTU |

| Relay Outputs | 4 SPDT relays (configurable) |

| Alarm Levels | Configurable High and Low Alarms |

| Operating Temperature | -20°C to 60°C |

| Humidity | 5% to 95% RH (Non-condensing) |

| Mounting Type | DIN Rail or Panel Mount |

| Compliance | CE, UL, CSA, ATEX, RoHS |

Product Applications

The Bently Nevada 1900/65A-00-00-01-00-00 universal monitoring system is widely used in industrial applications where real-time vibration and temperature monitoring is critical for ensuring operational efficiency and asset protection.

-

Pumps & Compressors – Prevents unexpected failures by continuously tracking vibration levels and bearing temperature.

-

Fans & Blowers – Ensures efficient operation and minimizes wear and tear through early fault detection.

-

Turbines & Generators – Provides real-time monitoring to prevent catastrophic failures in critical power generation equipment.

-

Gearboxes & Motors – Protects against overheating, misalignment, and excessive vibration in industrial drive systems.

-

Centrifuges & Mixers – Maintains optimal performance in chemical and pharmaceutical industries by detecting early-stage equipment degradation.

Product Advantages

-

Comprehensive Equipment Protection – Continuously monitors vibration, temperature, and other key parameters, ensuring reliable operation.

-

Versatile Input Compatibility – Supports multiple sensor types, including accelerometers, proximity probes, RTDs, and thermocouples, making it adaptable to various industrial applications.

-

Cost-Effective Alternative – Provides essential condition monitoring without the complexity and cost of a full-scale system like the Bently Nevada 3500 Series.

-

Flexible Installation Options – Designed for DIN rail or panel mounting, allowing easy integration into existing control panels.

-

Remote Monitoring Capability – With RS-485 Modbus RTU communication, the system can be connected to SCADA or DCS systems for real-time remote monitoring.

-

Configurable Alarm & Relay Outputs – Provides 4 independent SPDT relay outputs that can trigger alarms or shutdown actions based on set thresholds.

-

Industry-Standard Compliance – Certified for use in hazardous environments with CE, UL, CSA, ATEX, and RoHS approvals.

Brand and Series Information

- Brand: Bently Nevada

- Series: 1900/65A Universal Monitoring System

The Bently Nevada 1900/65A Series is designed for compact, cost-effective monitoring of rotating equipment, providing highly reliable condition monitoring and protection.

Related Models in the Same Series

| Model Number | Description | Channels | Input Types | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 1900/65A-01-00-01-00-00 | Universal Monitoring System | 4 | Vibration, Temp | 196.9 x 149.4 x 74.4 | 0.77 |

| 1900/65A-02-00-01-00-00 | Monitoring System with Ethernet | 4 | Vibration, Temp | 196.9 x 149.4 x 74.4 | 0.77 |

| 1900/65A-03-00-01-00-00 | Advanced Monitoring System | 4 | Vibration, Temp | 196.9 x 149.4 x 74.4 | 0.77 |

| 1900/65A-04-00-01-00-00 | Modbus-Enabled Monitoring System | 4 | Vibration, Temp | 196.9 x 149.4 x 74.4 | 0.77 |

| 1900/65A-05-00-01-00-00 | Monitoring System with Display | 4 | Vibration, Temp | 196.9 x 149.4 x 74.4 | 0.77 |

Popular Bently Nevada Models

| Model Number | Description | Channels | Input Types | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 3500/22M | Transient Data Interface | 16 | Vibration | 241 x 24 x 190 | 0.9 |

| 3500/42M | Proximitor Monitor | 4 | Proximity | 241 x 24 x 190 | 0.85 |

| 3500/93 | System Display Module | N/A | Display Module | 241 x 24 x 190 | 0.85 |

| 330104-00-14-10-02-00 | Accelerometer Sensor | N/A | Vibration Sensor | 32 x 32 x 64 | 0.3 |

| 330130-040-01-00 | Proximity Probe | N/A | Proximity | 40 x 40 x 80 | 0.2 |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 1900/65A monitoring system?

A1: The Bently Nevada 1900/65A is a universal equipment monitoring system designed for real-time condition monitoring and protection of rotating machinery by detecting vibration, temperature, and other critical parameters.

Q2: How many input channels does the 1900/65A have?

A2: The system has four configurable input channels, supporting vibration sensors, proximity probes, RTDs, and thermocouples.

Q3: What industries commonly use the 1900/65A?

A3: It is widely used in oil and gas, power generation, manufacturing, chemical processing, and other industries where machinery health monitoring is essential.

Q4: Can the 1900/65A be integrated with existing SCADA or DCS systems?

A4: Yes, the system supports RS-485 Modbus RTU communication, allowing seamless integration with SCADA, DCS, and other control systems for remote monitoring.

Q5: What power supply does the 1900/65A require?

A5: The system operates on 100-240V AC or 24V DC, providing flexibility for different industrial environments.

Q6: What are the mounting options for this monitoring system?

A6: It can be DIN rail-mounted or panel-mounted, making it easy to install in control cabinets and enclosures.

Q7: Does the system include alarm relays?

A7: Yes, the 1900/65A features four independent SPDT relay outputs, which can be configured for alarm or shutdown triggers.

Q8: What compliance certifications does the 1900/65A have?

A8: The system is certified for industrial use and meets CE, UL, CSA, ATEX, and RoHS standards, ensuring safe and reliable operation in harsh environments.

Q9: What is the operating temperature range of the 1900/65A?

A9: The system operates in temperatures from -20°C to 60°C, making it suitable for a wide range of industrial applications.

Q10: How does the 1900/65A compare to the Bently Nevada 3500 series?

A10: The 1900/65A is a cost-effective, standalone monitoring solution, ideal for applications that do not require a full-scale protection system like the Bently Nevada 3500 series, but still need reliable condition monitoring and early fault detection.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.