ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330930-060-01-05

- 3300 NSv Extension Cable

- USA

- 6m

- 0.09kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 8

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

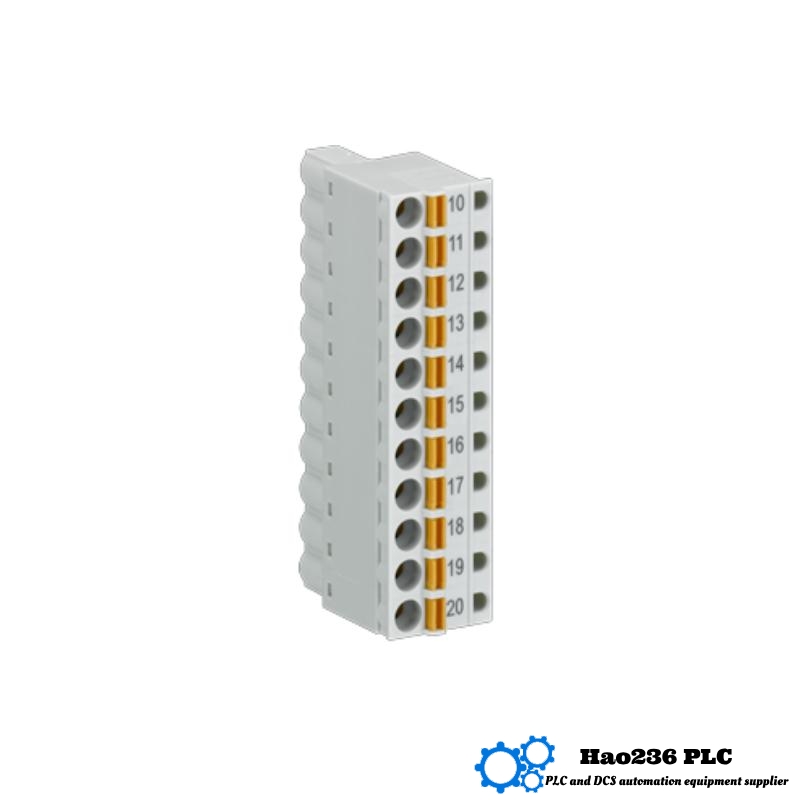

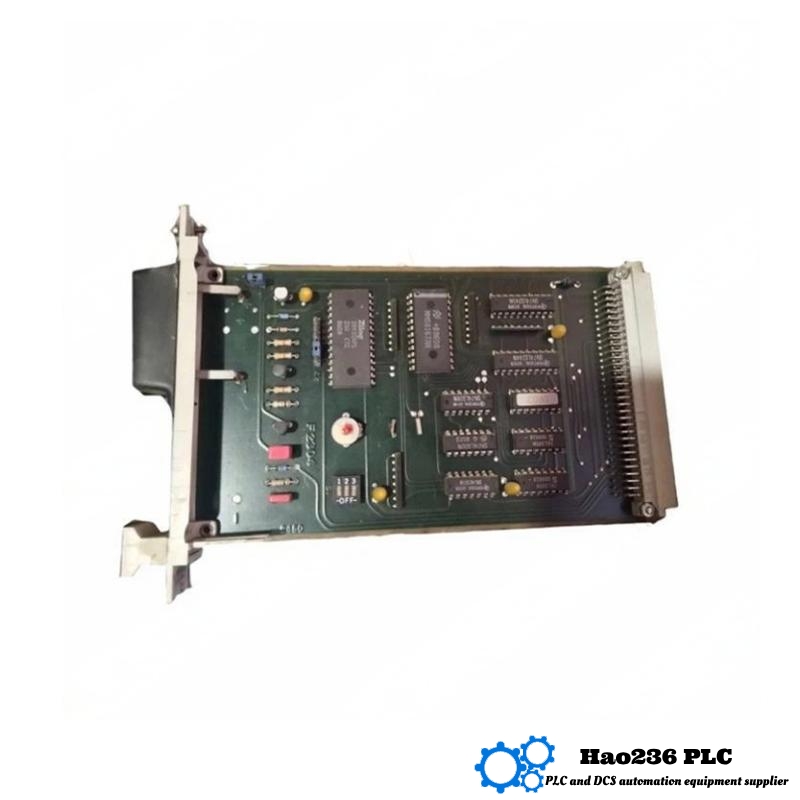

Bently Nevada 330930-060-01-05 3300 NSv Extension Cable

Product Overview

The Bently Nevada 330930-060-01-05 extension cable is a high-quality component designed for use with the 3300 NSv Series vibration monitoring systems. With a cable length of 6 meters, it allows for flexibility in the placement of vibration sensors, ensuring reliable and accurate data transmission even over long distances. This cable is engineered to work seamlessly with Bently Nevada’s advanced machinery monitoring technology, providing real-time vibration data crucial for industrial applications.

The extension cable is built for durability, capable of performing under harsh industrial conditions. It helps reduce downtime by enabling more efficient vibration monitoring setups in industries such as power generation, manufacturing, and oil & gas. With a lightweight design of only 0.09 kg, it can easily be deployed in various applications without compromising on performance.

Product Features

-

Cable Length: 6 meters, with other lengths available upon request

-

Weight: 0.09 kg

-

Material: Industrial-grade construction designed to withstand harsh environments

-

Signal Integrity: Ensures minimal signal degradation over long distances

-

Compatibility: Fully compatible with the 3300 NSv Series vibration sensors

-

Operating Temperature Range: -40°C to 85°C

-

Durability: Designed for long-term performance in industrial conditions

Applications

The 330930-060-01-05 extension cable is particularly beneficial in industrial environments where reliable vibration monitoring is essential. It is ideal for applications where vibration sensors need to be placed at a distance from the monitoring equipment. Key applications include:

-

Power Generation: Essential for monitoring turbines, compressors, and generators to detect potential issues early and prevent catastrophic failures.

-

Oil & Gas: Used in offshore rigs and pipelines where equipment is often spread out and difficult to access, allowing for continuous vibration monitoring.

-

Manufacturing: Helps in the installation of vibration sensors in large manufacturing facilities, ensuring machinery operates within safe parameters.

-

Industrial Equipment: Supports machinery health monitoring for motors, pumps, and compressors, providing a proactive approach to maintenance.

Advantages

-

Long-Distance Signal Integrity: The extension cable provides high-quality signal transmission over long distances, making it perfect for large industrial setups.

-

Lightweight and Flexible: Weighing only 0.09 kg, the cable is easy to handle and install, ensuring minimal impact on your existing equipment.

-

Durability: Built to endure tough environments, this extension cable is resistant to wear and tear, ensuring longevity in industrial applications.

-

Flexibility in Installation: With a length of 6 meters, the cable provides the flexibility needed to position vibration sensors in optimal locations.

-

Enhanced Equipment Monitoring: By extending the reach of vibration sensors, this cable helps in better monitoring of machinery, enhancing predictive maintenance efforts.

Brand and Series Information

-

Brand: Bently Nevada (a division of Baker Hughes)

-

Series: 3300 NSv Series

-

Product Type: Extension Cable for Vibration Sensors

Product Specifications

| Parameter | Value |

|---|---|

| Model | 330930-060-01-05 |

| Cable Length | 6 meters (custom lengths available) |

| Weight | 0.09 kg |

| Connector Type | 4-pin, compatible with 3300 NSv sensors |

| Signal Integrity | High-quality transmission over long distances |

| Material | Industrial-grade, rugged cable for harsh environments |

| Operating Temperature | -40°C to 85°C |

| Application | Vibration monitoring for industrial machinery |

| Standard | CE, UL certification |

Recommended Models from the Same Series (3300 NSv Series)

| Model | Description | Key Features |

|---|---|---|

| 330930-045-00-CN | 4.5-meter vibration sensor extension cable | Ideal for short to medium distances |

| 330930-042-00-CN | 6-meter vibration sensor extension cable | Reliable signal transmission for extended distances |

| 330930-043-00-CN | 5-meter vibration sensor extension cable | Flexible cable length for varied setups |

| 3300/12-01-00 | Vibration sensor for industrial applications | High precision for critical machinery monitoring |

| 330930-044-00-CN | 7-meter vibration sensor extension cable | Supports extended installation ranges |

Recommended Bently Nevada Products

| Model | Description | Key Features |

|---|---|---|

| 3300/20-02-00 | Vibration monitoring system with diagnostic capabilities | Provides reliable vibration data with early fault detection |

| 3300/10-01-00 | Proximity vibration sensor for industrial equipment | Rugged and sensitive sensor for critical machinery |

| 3300/18-01-00 | Vibration sensor with 4-20mA output | Ideal for integration with PLC systems |

| 330930-046-00-CN | 10-meter extension cable for vibration sensors | Perfect for large-scale industrial setups |

| 3300/06-01-00 | Analog vibration sensor with high sensitivity | Provides accurate vibration readings for machinery health monitoring |

Frequently Asked Questions (FAQ)

Q1: What is the length of the Bently Nevada 330930-060-01-05 extension cable?

A1: The cable is 6 meters long, but custom lengths are available if needed.

Q2: How much does the 330930-060-01-05 extension cable weigh?

A2: The extension cable weighs only 0.09 kg, making it easy to handle and install.

Q3: Can this extension cable be used with other vibration monitoring systems?

A3: No, the 330930-060-01-05 extension cable is specifically designed for use with Bently Nevada 3300 NSv Series vibration sensors.

Q4: What is the operating temperature range of this cable?

A4: The cable operates within a temperature range of -40°C to 85°C, suitable for most industrial environments.

Q5: What applications can the extension cable be used in?

A5: This cable is used for vibration monitoring in power generation, oil & gas, manufacturing, and other industrial applications.

Q6: Is the extension cable resistant to industrial conditions?

A6: Yes, the 330930-060-01-05 extension cable is built to withstand harsh industrial environments and offers long-term durability.

Q7: How does the extension cable maintain signal integrity?

A7: The cable is designed with high-quality materials that minimize signal degradation, ensuring accurate vibration monitoring over longer distances.

Q8: Can multiple extension cables be connected together?

A8: Yes, multiple cables can be connected to extend the distance even further, depending on the specific requirements of your setup.

Q9: Is this extension cable CE and UL certified?

A9: Yes, the 330930-060-01-05 extension cable meets CE and UL certification standards, ensuring safety and quality.

Q10: How does this cable support predictive maintenance?

A10: By providing reliable data transmission for vibration monitoring, the extension cable helps in early fault detection, which is essential for predictive maintenance.

Enhance Your Vibration Monitoring Flexibility

The Bently Nevada 330930-060-01-05 extension cable extends the reach of your vibration sensors by 6 meters, providing the flexibility needed to monitor large-scale machinery efficiently.

Lightweight, Reliable, Durable

At just 0.09 kg, the Bently Nevada 330930-060-01-05 extension cable is easy to handle and install. Designed for tough industrial conditions, it ensures long-lasting performance.

Seamless Signal Transmission at Long Distances

With minimal signal degradation over 6 meters, the Bently Nevada 330930-060-01-05 extension cable ensures accurate and reliable vibration monitoring, even in large industrial setups.

The Ideal Cable for Industrial Machinery Monitoring

Trust the Bently Nevada 330930-060-01-05 extension cable to deliver precise vibration data for your critical machinery, ensuring optimal performance and preventing downtime.