ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330980-51-05

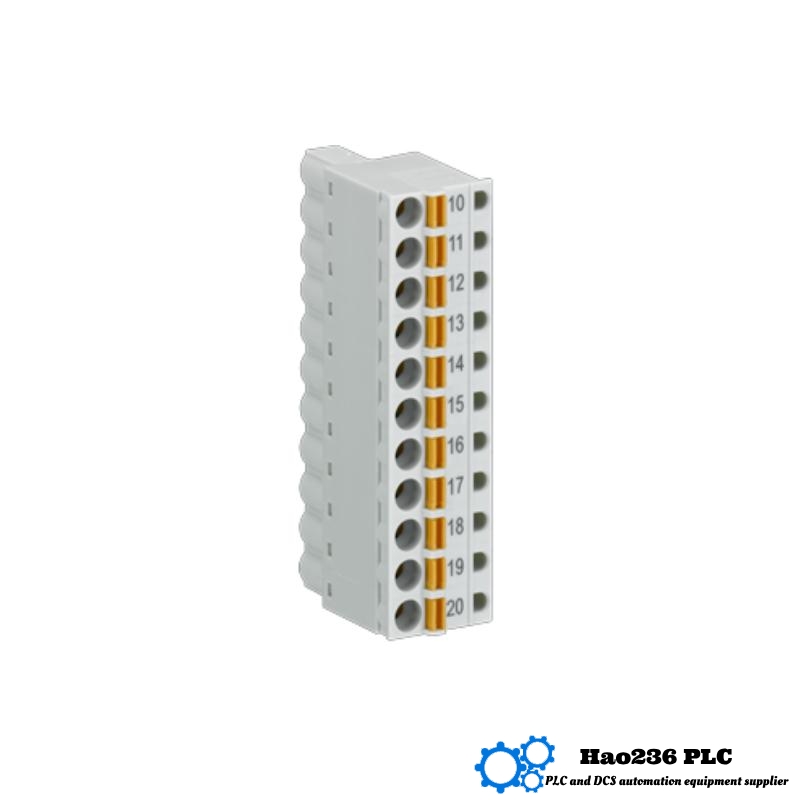

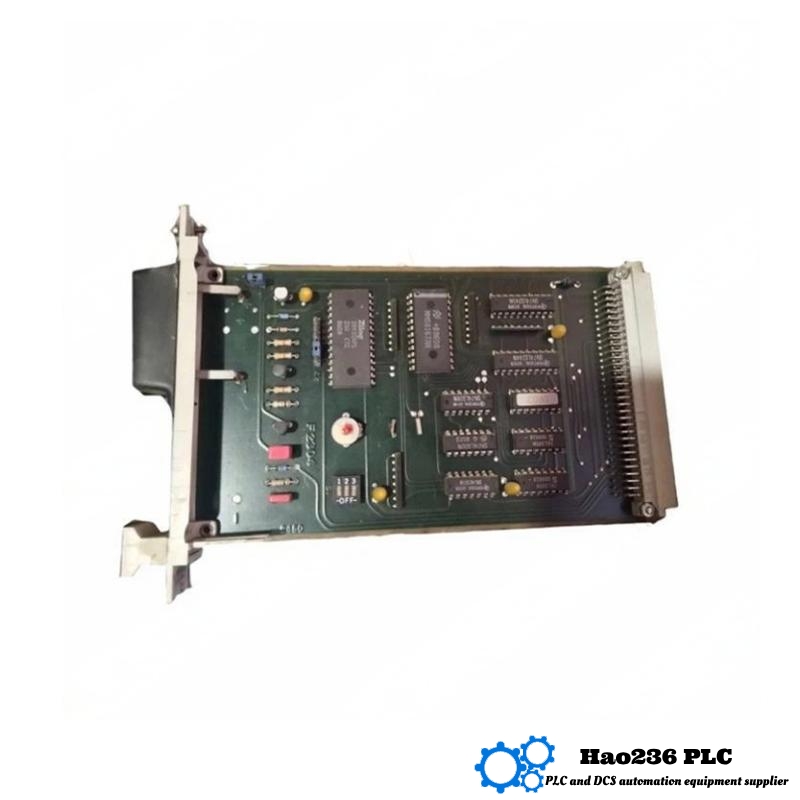

- 3300 XL NSv Front Sensor

- USA

- 81.3 x 61.2 x 63.5mm

- 0.5 kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 10

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Bently Nevada 330980-51-05 3300 XL NSv Front Sensor

Product Introduction

The Bently Nevada 330980-51-05 is a part of the highly trusted 3300 XL NSv series of proximity sensors. This front sensor is designed to provide reliable vibration and displacement monitoring for industrial machinery. It is engineered to detect misalignment, imbalance, and other machine faults in rotating machinery, thus preventing unnecessary breakdowns and extending the lifespan of critical equipment. The 3300 XL NSv front sensor is compatible with various monitoring systems and enhances predictive maintenance programs by providing accurate and continuous data.

Applications

-

Rotating machinery monitoring: The 3300 XL NSv Front Sensor is used for monitoring the health of rotating machinery like motors, pumps, and turbines.

-

Vibration detection: Ideal for identifying early signs of machine faults such as misalignment, unbalance, or bearing failure.

-

Condition-based monitoring: Often used in industries such as power generation, oil & gas, and chemical processing to ensure continuous operation of critical machinery.

Advantages

-

High accuracy: Provides precise measurement of vibration and displacement, which ensures early detection of machine faults.

-

Durable: Built with rugged components designed to withstand harsh industrial environments, offering reliability even under extreme conditions.

-

Easy integration: The sensor seamlessly integrates with existing Bently Nevada monitoring systems, making installation and system setup straightforward.

-

Low maintenance: Designed for long-lasting operation with minimal need for servicing or recalibration.

Brand: Bently Nevada

Bently Nevada is a recognized leader in condition monitoring technology, providing solutions that help businesses prevent unscheduled downtime and reduce maintenance costs. Their products are known for their reliability and advanced technology that supports critical equipment management across industries.

Series: 3300 XL NSv

The 3300 XL NSv series represents a set of sensors designed to meet the demands of industrial monitoring, providing enhanced performance, extended life, and improved reliability for critical machinery.

Specifications Table

| Feature | Description |

|---|---|

| Model | 330980-51-05 |

| Dimensions | 81.3 x 61.2 x 63.5 mm |

| Weight | 0.5 kg |

| Total Length | 5 m |

| Mounting Options | Available with different mounting configurations |

| Output | 4-20mA analog, compatible with 3300 XL system |

| Sensitivity | High sensitivity for vibration detection |

| Temperature Range | -40°C to +85°C |

| Protection | IP67-rated for dust and water resistance |

Recommended Models

5 Related Models (Same Series)

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 330980-50-05 | 3300 XL NSv Front Sensor | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 330980-51-10 | 3300 XL NSv Sensor with extended cable | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 330980-51-15 | 3300 XL NSv Front Sensor with different mounting | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 330980-52-00 | 3300 XL NSv Front Sensor (high sensitivity) | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 330980-53-00 | 3300 XL NSv Front Sensor (ruggedized) | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

5 Popular Bently Nevada Models

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 3300-05-01 | Vibration Sensor | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 3300-20-05 | Proximity Sensor | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 3500-40 | Vibration Transmitter | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 3500-44 | TDI Sensor | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

| 3500-45 | Integrated Vibration Monitoring | 81.3 x 61.2 x 63.5 mm | 0.5 kg |

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the 330980-51-05 sensor?

A1: The sensor operates within a temperature range of -40°C to +85°C.

Q2: Can the 330980-51-05 sensor be used with other brands of monitoring systems?

A2: No, this sensor is designed to integrate seamlessly with Bently Nevada’s 3300 XL monitoring systems.

Q3: How is the 330980-51-05 mounted on machinery?

A3: It can be mounted using a variety of configurations, including bolt-on, magnetic, or threaded options.

Q4: What type of output does the 330980-51-05 provide?

A4: The sensor outputs a 4-20mA analog signal, compatible with Bently Nevada monitoring systems.

Q5: Is the 330980-51-05 sensor suitable for high vibration environments?

A5: Yes, it is designed to withstand high vibration environments typical in industrial settings.

Q6: What is the lifespan of the 330980-51-05 sensor?

A6: The sensor is built for long-term operation with minimal maintenance, typically lasting for years with proper care.

Q7: Can the sensor be used in outdoor installations?

A7: Yes, the sensor is IP67-rated, making it suitable for use in harsh outdoor environments.

Q8: Is the sensor easy to install?

A8: Yes, it is easy to install, especially when integrated with Bently Nevada’s monitoring system.

Q9: What kind of maintenance is required for the 330980-51-05?

A9: The sensor requires minimal maintenance, mainly ensuring that the sensor’s mounting is secure and that the system is properly calibrated.

Q10: What is the sensor’s weight?

A10: The sensor weighs 0.5 kg.

Enhance Reliability, Minimize Downtime

Maximize your machinery’s uptime with the 3300 XL NSv Front Sensor. Reliable monitoring for a more efficient operation.

Precision Monitoring for Every Machine

Get the most accurate vibration data with the 3300 XL NSv Front Sensor, engineered for precision.

Built to Last in Harsh Environments

The 3300 XL NSv Front Sensor is designed to withstand extreme conditions, delivering performance you can count on.

Keep Your Machinery Running Smoothly

Use the 3300 XL NSv Front Sensor to ensure your equipment operates smoothly and efficiently, minimizing unexpected failures.