ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/22M-01-01-00

- Transient Data Interface Module

- USA

- 241.3 x 24.4 x 241.8 mm

- 0.91kg

- 288055-01

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 6

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

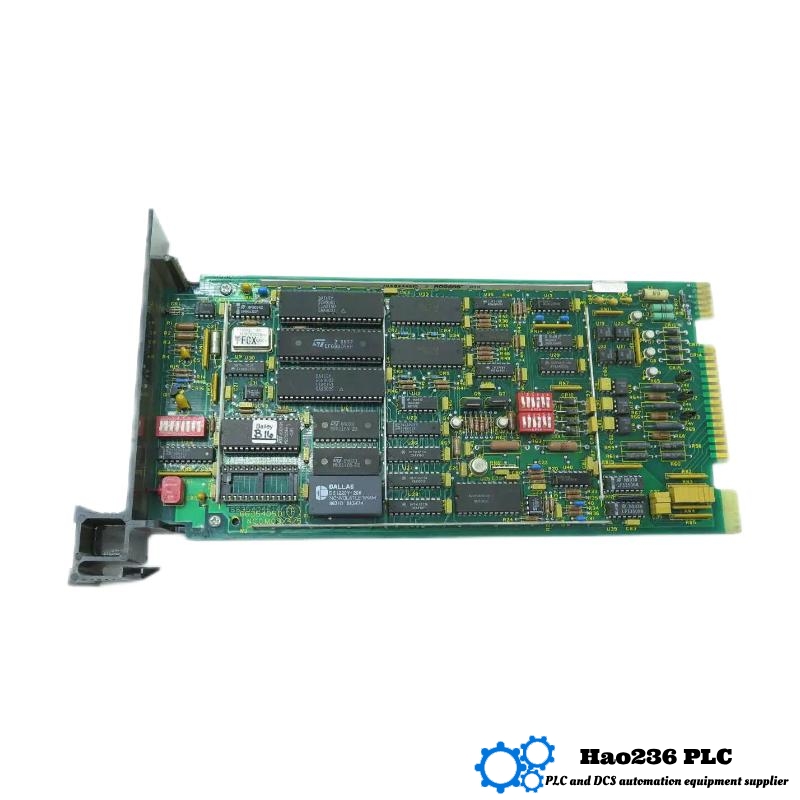

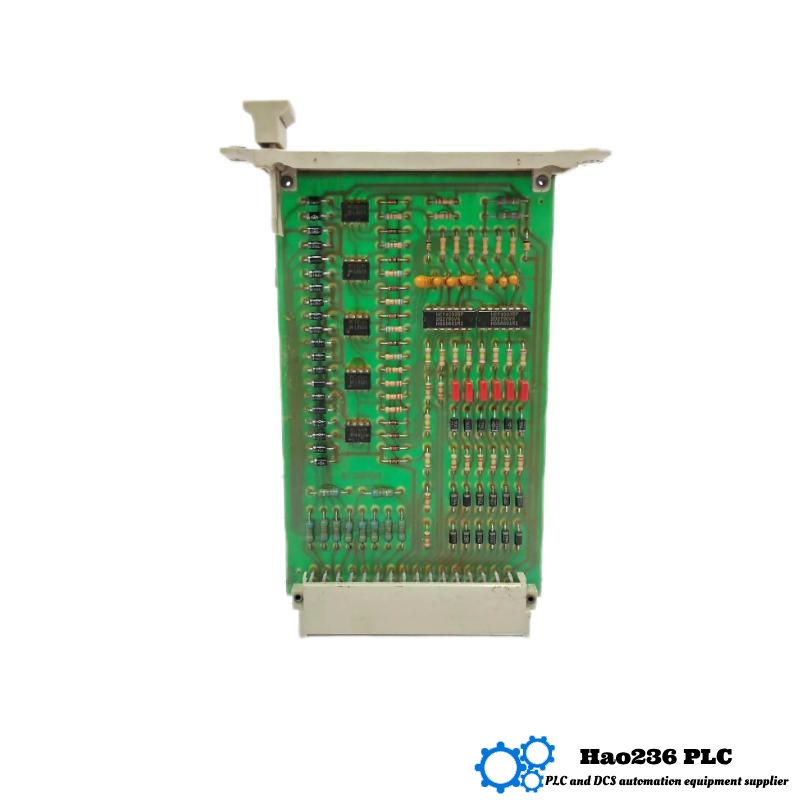

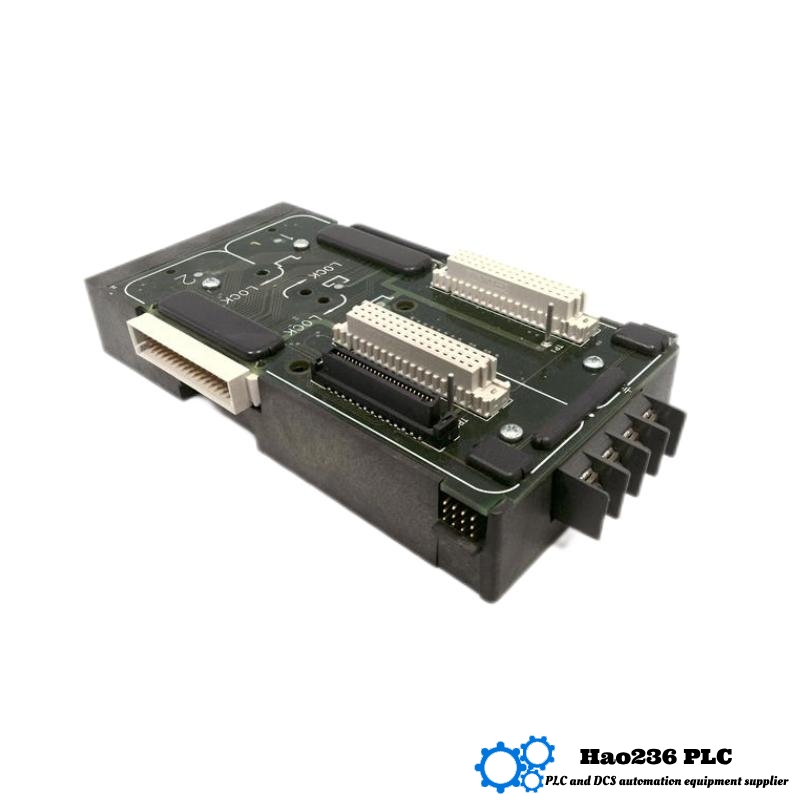

Bently Nevada 3500/22M-01-01-00 288055-01 Transient Data Interface Module

Product Introduction

The Bently Nevada 3500/22M-01-01-00 288055-01 is a specialized transient data interface module designed for high-precision monitoring of machinery dynamics. It is a key component in the Bently Nevada 3500 Series of machinery protection and condition monitoring systems. This module is designed to capture transient data, such as vibration signals and other high-frequency disturbances, that are critical for monitoring the health and performance of rotating machinery. With real-time monitoring and high-accuracy data acquisition, the 3500/22M-01-01-00 helps in early detection of faults, enabling predictive maintenance and minimizing the risk of unplanned downtime.

The Bently Nevada 3500/22M-01-01-00 module is particularly useful for industries where machinery reliability is paramount, such as power generation, oil and gas, manufacturing, and aerospace. It integrates seamlessly with other modules in the 3500 Series, offering a comprehensive monitoring solution that helps operators ensure the optimal performance and longevity of critical machinery.

Product Applications

The 3500/22M-01-01-00 is designed to be used across a variety of industrial sectors that rely on rotating machinery for critical operations. Its primary applications include:

-

Power Generation: Monitoring turbines, generators, and other critical equipment to ensure stable operation and prevent failures.

-

Oil and Gas: Protection of offshore platforms, compressors, and pumps, enabling operators to detect issues before they lead to equipment failure.

-

Manufacturing: Monitoring pumps, motors, and other machinery to maintain productivity and avoid unplanned shutdowns.

-

Mining: Monitoring high-value mining equipment, such as crushers and mills, to ensure smooth operation and minimize costly repairs.

-

Aerospace: Ensuring the performance of critical systems in aerospace machinery, providing early warning of performance issues.

Product Advantages

-

High-Precision Transient Data Acquisition: The 3500/22M-01-01-00 captures high-frequency transient data with precision, enabling detailed analysis of machinery dynamics.

-

Early Fault Detection: By monitoring transient behaviors, the module helps identify early signs of faults in rotating machinery, leading to proactive maintenance and reduced downtime.

-

Seamless Integration: It integrates effortlessly with other Bently Nevada 3500 Series modules, forming a comprehensive system for machinery protection and condition monitoring.

-

Real-Time Monitoring: The module provides continuous, real-time data on machinery performance, allowing for immediate detection of abnormalities and quick response.

-

Durability and Reliability: Built to withstand harsh industrial environments, the 3500/22M-01-01-00 is a reliable component in maintaining the health of critical assets.

-

Cost-Effective: By enabling condition-based monitoring, the module reduces the need for unnecessary maintenance and repairs, leading to cost savings.

Brand Information

Bently Nevada is a trusted global leader in machinery protection and condition monitoring. As a subsidiary of Baker Hughes, Bently Nevada is known for developing advanced solutions for ensuring the reliability and performance of rotating machinery. Their products are highly regarded for their precision, reliability, and ease of integration into existing systems. The company’s solutions are widely used across industries such as power generation, oil and gas, manufacturing, and mining, providing valuable insights into the health of critical assets.

Product Series

The Bently Nevada 3500 Series is a comprehensive suite of monitoring and protection modules that work together to safeguard the performance of industrial machinery. The series includes various modules such as vibration monitors, transient data modules, temperature, and pressure sensors, providing a flexible and scalable solution for machinery condition monitoring. These modules are designed to deliver accurate and real-time data, enabling operators to detect and resolve issues before they lead to costly breakdowns.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/22M-01-01-00 288055-01 |

| Module Type | Transient Data Interface |

| Dimensions (WxHxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Power Supply | 24 V DC |

| Input Type | Transient Data from Rotating Machinery |

| Operating Temperature | -40°C to 85°C |

| Mounting | Rack-Mountable (3500 Rack) |

| Signal Type | Vibration, Displacement, and Other Transients |

| Compatibility | Compatible with 3500 Series Modules |

| Interface | Direct interface with 3500 system |

Related Models in the Same Series

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/22M-01-02 | 241.3 x 24.4 x 241.8 mm | 0.91 kg | Extended transient data module with more input channels |

| 3500/22M-01-03 | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Includes advanced data processing features |

| 3500/21M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.90 kg | Standard data acquisition module for rotating machinery |

| 3500/19M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.93 kg | Analog data acquisition module for general machinery |

| 3500/27M-01-01 | 241.3 x 24.4 x 241.8 mm | 1.00 kg | High-capacity data interface with expanded input/output channels |

Popular Bently Nevada Models

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/42M | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Machinery protection and condition monitoring system |

| 3500/53 | 241.3 x 24.4 x 241.8 mm | 1.10 kg | Vibration monitoring system for critical machinery |

| 3500/72 | 241.3 x 24.4 x 241.8 mm | 0.95 kg | Remote monitoring system for critical assets |

| 3500/71M | 241.3 x 24.4 x 241.8 mm | 1.05 kg | Digital control and protection system for motors and generators |

| 3500/35 | 241.3 x 24.4 x 241.8 mm | 0.85 kg | Analog input module for monitoring of machinery performance |

Frequently Asked Questions (FAQ)

Q1: What does the Bently Nevada 3500/22M-01-01-00 module do?

A1: The module captures transient data from rotating machinery, such as vibrations and other high-frequency signals, to provide real-time monitoring and diagnostics of machinery health.

Q2: How can the 3500/22M-01-01-00 module help reduce downtime?

A2: By detecting early signs of wear or faults, the module enables predictive maintenance, allowing maintenance teams to address issues before they lead to unplanned downtime.

Q3: What types of machinery can be monitored with this module?

A3: It is suitable for monitoring turbines, compressors, pumps, motors, and other types of rotating machinery used in industries like power generation, oil and gas, and manufacturing.

Q4: Is the 3500/22M-01-01-00 compatible with other Bently Nevada modules?

A4: Yes, it is fully compatible with other modules in the Bently Nevada 3500 Series, allowing for seamless integration into a comprehensive machinery protection system.

Q5: What is the power requirement for the 3500/22M-01-01-00?

A5: The module operates with a 24 V DC power supply.

Q6: What environments can this module operate in?

A6: It is designed to operate in harsh industrial environments with an operating temperature range of -40°C to 85°C.

Q7: How is the 3500/22M-01-01-00 module mounted?

A7: It is rack-mountable and is designed to be installed in a standard Bently Nevada 3500 rack.

Q8: Does this module provide real-time data?

A8: Yes, the module continuously monitors and provides real-time data for early detection of any developing issues.

Q9: What industries commonly use this module?

A9: It is used in industries such as power generation, oil and gas, manufacturing, mining, and aerospace for machinery monitoring.

Q10: What type of data does this module collect?

A10: It collects transient data such as vibration and displacement signals, which are essential for understanding the health of rotating machinery.

Maximize Your Machinery Uptime with the Bently Nevada 3500/22M

Protect your critical machinery with the Bently Nevada 3500/22M transient data module, designed to provide real-time monitoring and early detection of potential failures.

Prevent Downtime Before It Starts – Bently Nevada 3500/22M

The Bently Nevada 3500/22M is your proactive solution to avoiding unexpected breakdowns. By detecting faults early with real-time transient data monitoring, safeguard your operations and reduce downtime.

Maximize Asset Reliability with Bently Nevada 3500/22M

Achieve unparalleled machinery reliability with Bently Nevada's 3500/22M transient data module. Experience precise fault detection and increase the longevity of your critical assets with proactive monitoring.

Revolutionize Your Maintenance Strategy with the 3500/22M

Reimagine how you approach maintenance with Bently Nevada’s 3500/22M module. Leverage high-precision transient data to stay ahead of potential issues and ensure continuous operation of your most valuable machinery.