ProductPRODUCT

Featured products

Contact Us

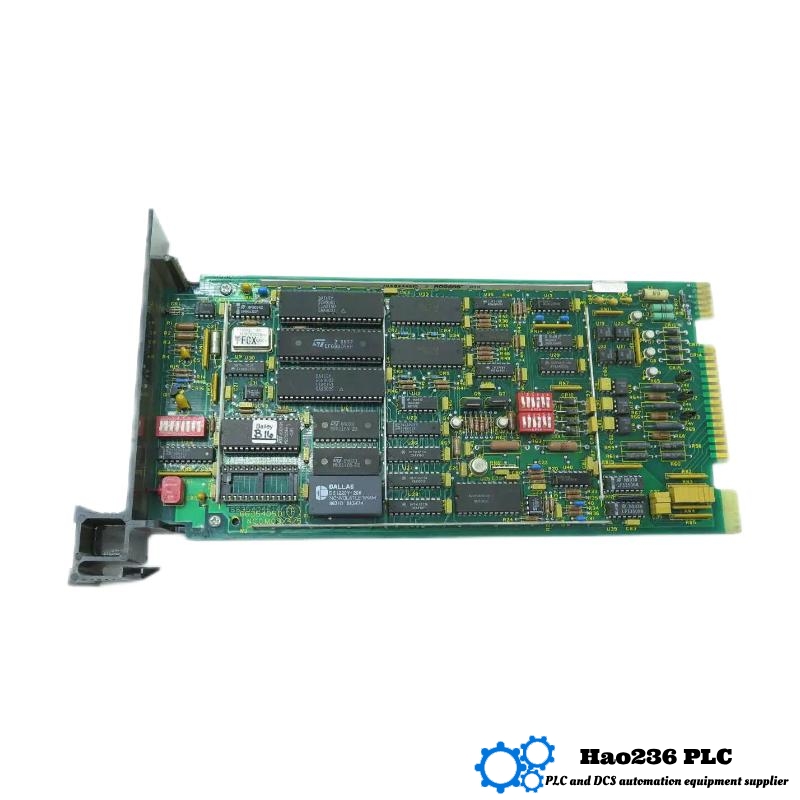

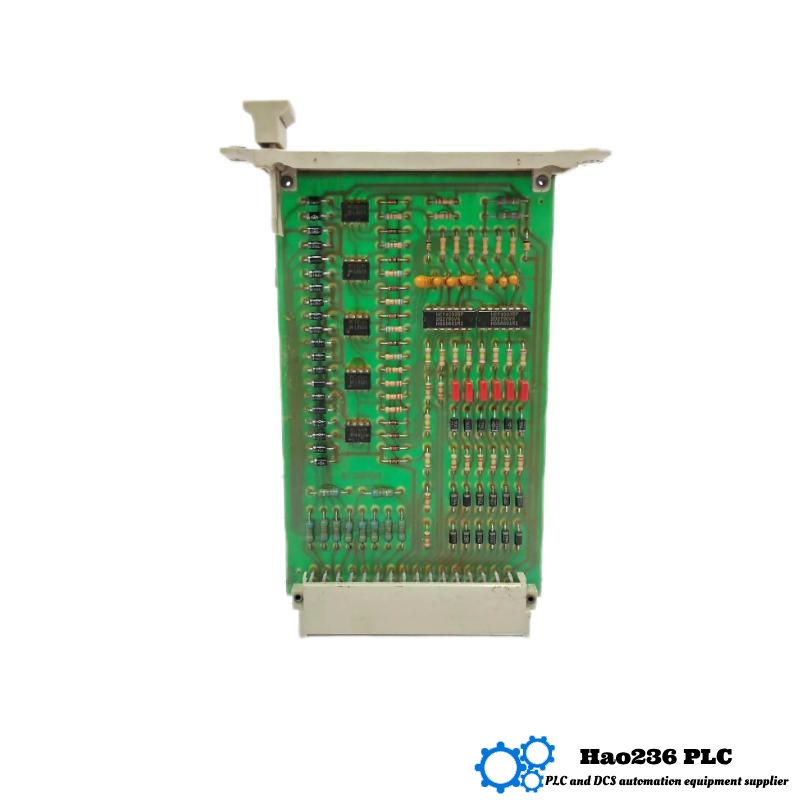

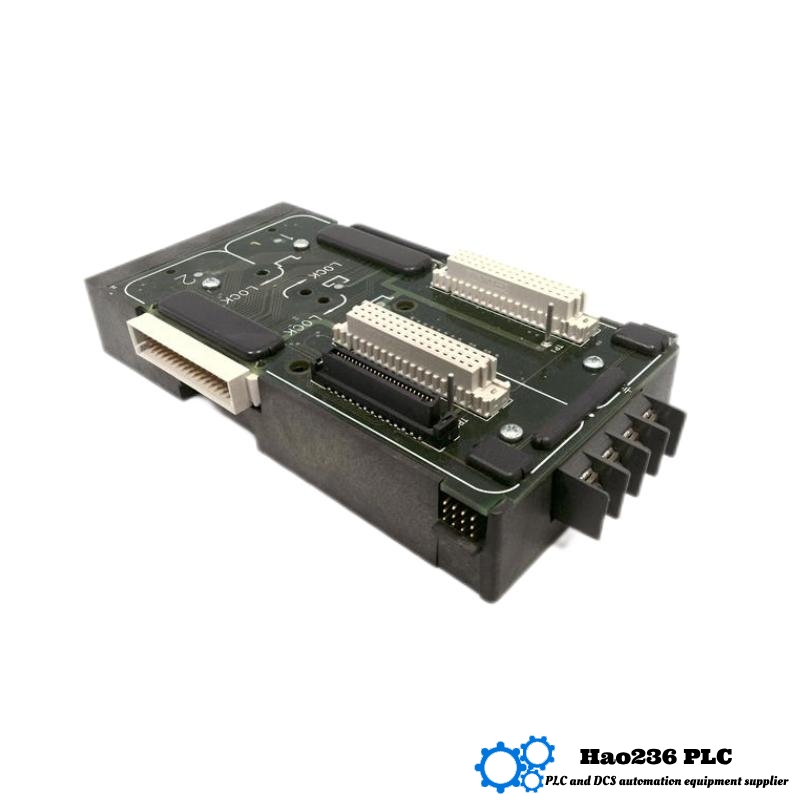

- Bently Nevada

- 3500/22M-01-01-00

- Transient Data Interface Module

- USA

- 241.3 x 24.4 x 241.8 mm

- 0.91kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 4

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Bently Nevada 3500/22M-01-01-00 Transient Data Interface Module

Product Introduction

The Bently Nevada 3500/22M-01-01-00 Transient Data Interface Module is a high-performance module designed for use within the Bently Nevada 3500 machinery protection and condition monitoring systems. It specializes in capturing transient data, such as high-frequency vibration, displacement, and other dynamic behaviors of rotating machinery. By enabling detailed analysis of these transient signals, this module provides real-time insight into machinery health, allowing operators to detect potential issues before they result in unplanned downtime or catastrophic failure.

As part of the Bently Nevada 3500 Series, the 3500/22M-01-01-00 integrates seamlessly into the broader monitoring system. It is designed to capture critical data that can be used for predictive maintenance, allowing companies to reduce operating costs by maintaining machinery only when necessary, based on real-time data.

Product Applications

-

Rotating Machinery Monitoring: The 3500/22M-01-01-00 is ideal for monitoring high-speed rotating machinery, including turbines, compressors, motors, and pumps, to detect faults such as imbalance, misalignment, or bearing wear.

-

Predictive Maintenance: By capturing transient data, the module allows for early detection of potential problems, facilitating proactive maintenance and reducing costly repairs or unexpected downtime.

-

Power Generation: The module is widely used in power plants to monitor critical assets such as turbines and generators, ensuring their performance and preventing failure.

-

Oil and Gas: In the oil and gas industry, this module is vital for monitoring rotating machinery in offshore platforms and refineries.

-

Industrial Applications: This module is used across manufacturing plants, including applications that require precise machinery monitoring for predictive maintenance and reliability.

Product Advantages

-

High Precision Data: The 3500/22M-01-01-00 module collects transient data with high accuracy, ensuring that any early signs of machine degradation are captured.

-

Enhanced Protection: By continuously monitoring transient data, the module provides early warnings of potential machine failure, thus preventing costly damage and downtime.

-

Seamless Integration: This module easily integrates with other Bently Nevada 3500 Series components, offering a scalable solution for machine condition monitoring.

-

Real-Time Analysis: It allows for real-time monitoring of machinery health, enabling immediate action when needed to avoid unexpected failures.

-

Compact Design: The module has a compact size and is designed for easy installation within a standard Bently Nevada 3500 rack, saving valuable space.

-

Reliability in Harsh Conditions: Engineered to withstand harsh industrial environments, the 3500/22M-01-01-00 operates reliably in a wide range of temperatures and conditions.

Brand Information

Bently Nevada, part of Baker Hughes, is an industry leader in providing condition monitoring and protection solutions for machinery. Their products, including the 3500 Series, are renowned for their accuracy, reliability, and ability to provide real-time diagnostics for critical equipment. The brand is trusted by industries worldwide to help optimize asset performance, reduce downtime, and improve safety.

Product Series

The Bently Nevada 3500 Series is a comprehensive suite of products designed for machinery protection and condition monitoring. It includes modules for vibration monitoring, temperature measurement, pressure monitoring, and data acquisition, all designed to work together in a cohesive system. The 3500 Series is widely recognized for its ability to enhance the performance and reliability of critical machinery, making it an essential solution for industries such as power generation, oil and gas, and manufacturing.

Product Parameters

| Parameter | Value |

|---|---|

| Module Type | Transient Data Interface |

| Dimensions (WxHxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Power Supply | 24 V DC |

| Input Type | Transient Data from Rotating Machinery |

| Operating Temperature | -40°C to 85°C |

| Mounting | Rack-Mountable (3500 Rack) |

| Signal Type | Vibration, Displacement, and Other Transients |

| Compatibility | Compatible with 3500 Series Modules |

| Interface | Direct interface with 3500 system |

Related Models in the Same Series

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/22M-01-02 | 241.3 x 24.4 x 241.8 mm | 0.91 kg | Extended transient data module with more input channels |

| 3500/22M-01-03 | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Includes advanced data processing features |

| 3500/21M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.90 kg | Standard data acquisition module for rotating machinery |

| 3500/19M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.93 kg | Analog data acquisition module for general machinery |

| 3500/27M-01-01 | 241.3 x 24.4 x 241.8 mm | 1.00 kg | High-capacity data interface with expanded input/output channels |

Popular Bently Nevada Models

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/42M | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Machinery protection and condition monitoring system |

| 3500/53 | 241.3 x 24.4 x 241.8 mm | 1.10 kg | Vibration monitoring system for critical machinery |

| 3500/72 | 241.3 x 24.4 x 241.8 mm | 0.95 kg | Remote monitoring system for critical assets |

| 3500/71M | 241.3 x 24.4 x 241.8 mm | 1.05 kg | Digital control and protection system for motors and generators |

| 3500/35 | 241.3 x 24.4 x 241.8 mm | 0.85 kg | Analog input module for monitoring of machinery performance |

Frequently Asked Questions (FAQ)

Q1: What is the main function of the Bently Nevada 3500/22M-01-01-00 module?

A1: This module is designed to capture transient data from rotating machinery, providing real-time monitoring and diagnostics to ensure machinery operates at optimal levels.

Q2: How does this module benefit predictive maintenance?

A2: By capturing transient signals, the module helps detect potential issues early, allowing maintenance to be performed only when necessary, which reduces costs and downtime.

Q3: What type of equipment can the 3500/22M-01-01-00 module monitor?

A3: It is designed to monitor rotating machinery, such as turbines, pumps, compressors, and motors, offering insights into their condition and performance.

Q4: Is the Bently Nevada 3500/22M-01-01-00 compatible with other Bently Nevada modules?

A4: Yes, this module is fully compatible with other components in the Bently Nevada 3500 Series, ensuring seamless integration for comprehensive machinery monitoring.

Q5: What power requirements does the 3500/22M-01-01-00 module have?

A5: The module operates with a 24 V DC power supply, which is common for industrial monitoring systems.

Q6: Can this module operate in extreme conditions?

A6: Yes, it is designed to function within a wide temperature range of -40°C to 85°C, making it suitable for a variety of industrial environments.

Q7: How is this module mounted?

A7: The module is rack-mountable and designed to be installed in a standard 3500 Series rack, providing ease of installation and maintenance.

Q8: Does this module require special software for operation?

A8: Yes, it integrates with Bently Nevada’s System 1 and other compatible software, enabling real-time data analysis and diagnostics.

Q9: What industries typically use the 3500/22M-01-01-00 module?

A9: It is commonly used in industries such as power generation, oil and gas, manufacturing, and any industry with critical rotating machinery that requires monitoring.

Q10: What kind of data does this module capture?

A10: The module captures transient data such as vibration, displacement, and other high-frequency signals that are crucial for understanding the dynamic behavior of machinery.

Precision Monitoring at Its Best – Bently Nevada 3500/22M

Capture critical transient data with the Bently Nevada 3500/22M module, the ultimate solution for machinery protection and predictive maintenance.

Stay Ahead of Failures with Bently Nevada 3500/22M

Ensure your machinery operates smoothly with real-time transient data analysis, reducing the risk of unplanned downtime and costly repairs.

Protect What Matters – Bently Nevada 3500/22M Module

Guard your assets with Bently Nevada's advanced transient data interface, designed to detect potential failures before they happen.

The Future of Machine Monitoring – Bently Nevada 3500/22M

Maximize machine performance and extend equipment life with the Bently Nevada 3500/22M, the future of machinery protection and condition monitoring.