ProductPRODUCT

Featured products

Contact Us

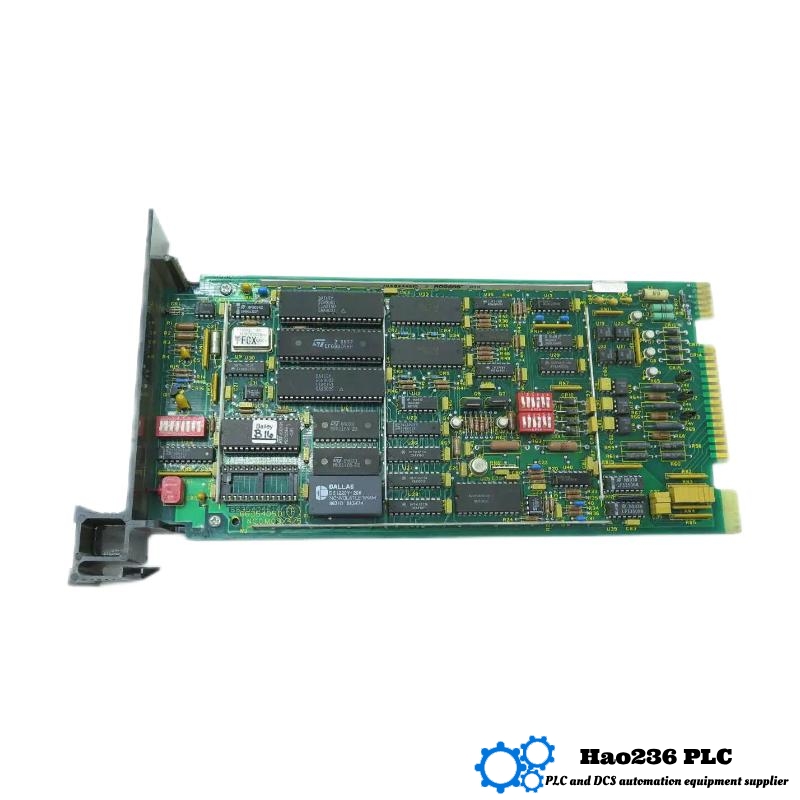

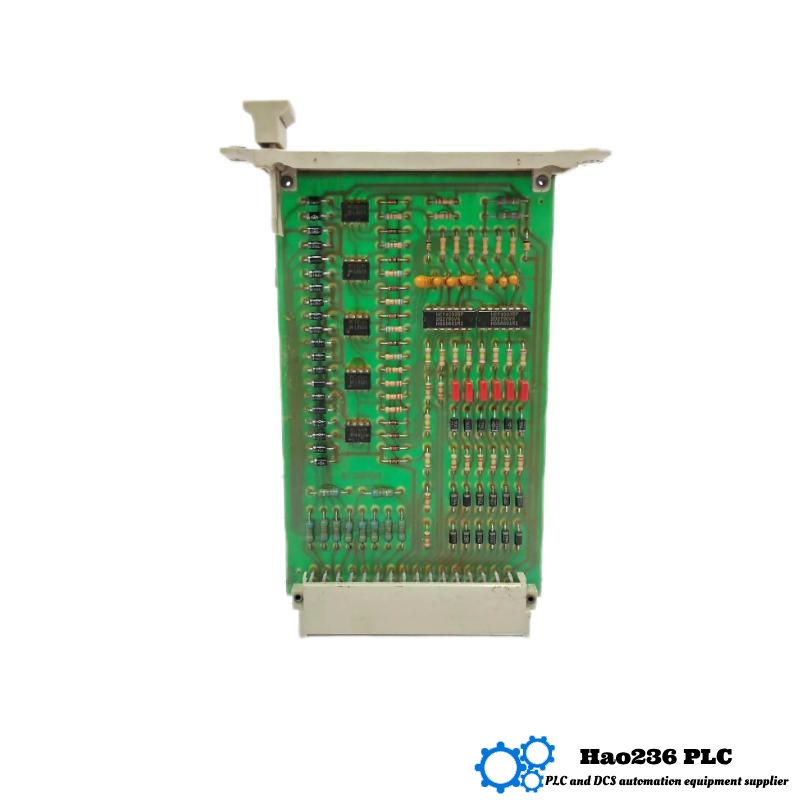

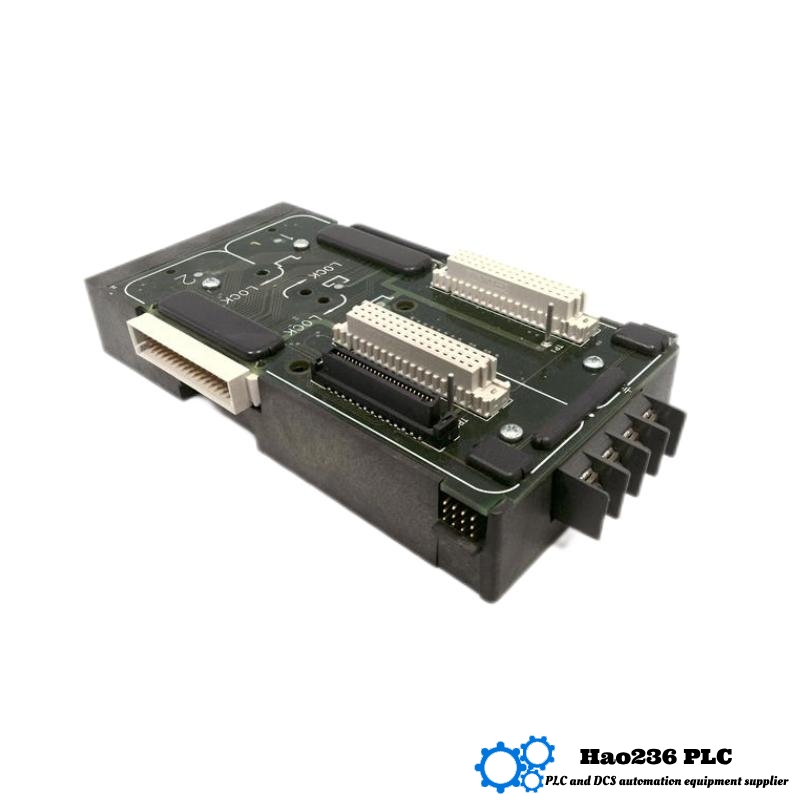

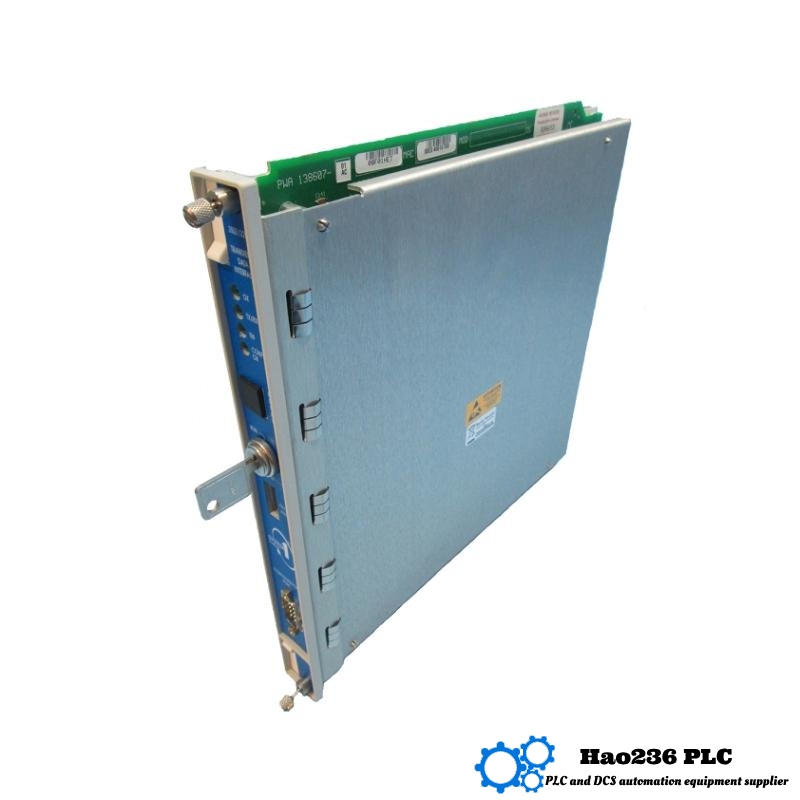

- Bently Nevada

- 3500/22M-01-01

- Transient Data Interface Module

- USA

- 241.3 x 24.4 x 241.8 mm

- 0.91kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 3

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Bently Nevada 3500/22M-01-01 Transient Data Interface Module

Product Introduction

The Bently Nevada 3500/22M-01-01 Transient Data Interface Module is a critical component in the monitoring and protection of rotating machinery. Part of the Bently Nevada 3500 series, this module enables the acquisition and analysis of transient data, providing essential insights into the dynamic behavior of machinery. It is specifically designed to interface with Bently Nevada’s 3500 series machinery protection systems, facilitating the collection of high-frequency vibration, displacement, and other transient signals for real-time diagnostics and monitoring.

This module supports advanced machinery monitoring systems, offering an invaluable tool for operators who need to ensure equipment is functioning at optimal levels, helping prevent unexpected downtime and costly repairs. It is engineered to operate seamlessly with other components in the 3500 series, forming a robust system for machinery health monitoring and protection.

Product Applications

-

Rotating Machinery Monitoring: Used for continuous monitoring of pumps, motors, turbines, compressors, and other machinery.

-

Predictive Maintenance: Helps detect early signs of machinery wear, imbalance, or misalignment by analyzing transient data, enabling proactive maintenance and minimizing downtime.

-

Condition-Based Monitoring: Provides data on critical machine conditions, helping engineers make informed decisions regarding operations and maintenance.

-

Oil and Gas Industry: Suitable for monitoring critical rotating equipment in oil refineries, offshore rigs, and pipelines.

-

Power Generation: Essential for safeguarding turbines, generators, and other high-speed equipment in power plants.

Product Advantages

-

High-Fidelity Data: Provides high-precision, transient data capture for accurate machine diagnostics.

-

Enhanced Protection: Ensures early detection of faults by capturing transient conditions that might not be visible with standard monitoring systems.

-

Seamless Integration: Fully compatible with the Bently Nevada 3500 system, making integration into existing monitoring frameworks easy.

-

Real-Time Monitoring: Transient data can be analyzed in real-time, offering immediate insights into machine performance.

-

Compact and Robust: Designed to function reliably even in harsh industrial environments, with a durable and compact design.

-

Reduced Maintenance Costs: By enabling early fault detection, the 3500/22M module helps prevent catastrophic failures and reduce maintenance costs.

Brand Information

Bently Nevada, a subsidiary of Baker Hughes, is a leading provider of machine condition monitoring and asset protection solutions. The company has pioneered the development of advanced machinery protection and diagnostic systems, trusted by industries around the globe. The Bently Nevada 3500/22M-01-01 module reflects the company’s commitment to delivering top-quality solutions for real-time machinery monitoring, ensuring both reliability and high performance.

Product Series

This module belongs to the Bently Nevada 3500 Series, a comprehensive suite of machinery protection and condition monitoring products. The series is renowned for its ability to provide continuous surveillance of mechanical and electrical systems, offering predictive maintenance tools and protection for critical machinery across various industries.

Product Parameters

| Parameter | Value |

|---|---|

| Module Type | Transient Data Interface |

| Dimensions (WxHxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Input Type | Transient Data from Rotating Machinery |

| Power Supply | 24 V DC |

| Operating Temperature | -40°C to 85°C |

| Mounting | Rack-Mountable (3500 Rack) |

| Compatibility | Compatible with 3500 Series Modules |

| Signal Type | Vibration, Displacement, and Other Transients |

| Interface | Direct interface with 3500 system |

Related Models in the Same Series

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/22M-01-02 | 241.3 x 24.4 x 241.8 mm | 0.91 kg | Extended transient data module with more input channels |

| 3500/22M-01-03 | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Includes advanced data processing features |

| 3500/21M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.90 kg | Standard data acquisition module for rotating machinery |

| 3500/19M-01-01 | 241.3 x 24.4 x 241.8 mm | 0.93 kg | Analog data acquisition module for general machinery |

| 3500/27M-01-01 | 241.3 x 24.4 x 241.8 mm | 1.00 kg | High-capacity data interface with expanded input/output channels |

Popular Bently Nevada Models

| Model | Dimensions | Weight | Description |

|---|---|---|---|

| 3500/42M | 241.3 x 24.4 x 241.8 mm | 0.92 kg | Machinery protection and condition monitoring system |

| 3500/53 | 241.3 x 24.4 x 241.8 mm | 1.10 kg | Vibration monitoring system for critical machinery |

| 3500/72 | 241.3 x 24.4 x 241.8 mm | 0.95 kg | Remote monitoring system for critical assets |

| 3500/71M | 241.3 x 24.4 x 241.8 mm | 1.05 kg | Digital control and protection system for motors and generators |

| 3500/35 | 241.3 x 24.4 x 241.8 mm | 0.85 kg | Analog input module for monitoring of machinery performance |

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the Bently Nevada 3500/22M-01-01 module?

A1: This module is designed to interface with rotating machinery, capturing transient data such as vibration and displacement to support machine condition monitoring and protection.

Q2: Can this module be used with any machine?

A2: The 3500/22M-01-01 module is specifically engineered for integration with Bently Nevada’s 3500 Series monitoring system, ensuring compatibility with the brand’s machinery protection setup.

Q3: How does the 3500/22M-01-01 module help in predictive maintenance?

A3: By capturing transient data, this module identifies abnormal conditions early, helping operators anticipate and prevent costly machine failures through predictive maintenance.

Q4: What types of signals can the module measure?

A4: The module measures transient signals such as vibration and displacement, which are crucial for understanding the dynamic behavior of rotating machinery.

Q5: Does this module require special software for operation?

A5: The 3500/22M-01-01 module integrates seamlessly with the Bently Nevada System 1 and other compatible Bently Nevada software for data analysis and diagnostics.

Q6: What are the power requirements for the module?

A6: The 3500/22M-01-01 module operates on a 24 V DC power supply, which is typical for control and protection systems in industrial environments.

Q7: Can this module be used in extreme temperatures?

A7: Yes, it is designed to operate in a wide range of temperatures from -40°C to 85°C, making it suitable for a variety of industrial environments.

Q8: How is the module mounted?

A8: It is designed to be mounted in a standard 3500 series rack, which is typically used in large-scale industrial machinery monitoring systems.

Q9: Is this module compatible with other Bently Nevada products?

A9: Yes, it is fully compatible with other Bently Nevada 3500 series modules, forming a cohesive and robust machinery protection system.

Q10: What industries can benefit from the 3500/22M-01-01 module?

A10: Industries such as power generation, oil and gas, manufacturing, and mining, where rotating machinery is critical, will benefit from the insights this module provides into machine health.

Unleash the Power of Precision – Bently Nevada 3500/22M

Take control of your machinery health with Bently Nevada’s 3500/22M module, the key to proactive maintenance and enhanced machine protection.

Stay Ahead of Failures – Bently Nevada 3500/22M Transient Data Module

Capture critical transient data in real-time with Bently Nevada’s 3500/22M, and ensure your machinery runs smoothly for longer.

Real-Time Insights for Maximum Protection – Bently Nevada 3500/22M

Monitor rotating machinery like never before with the 3500/22M module. Real-time transient data empowers you to prevent downtime before it occurs.

Guard Your Assets with Bently Nevada 3500/22M

Protect your most valuable assets with the Bently Nevada 3500/22M module, offering superior transient data collection for optimal machinery performance.