ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 990-05-XX-03-05

- Vibration Transmitter

- USA

- 100.1 x 73.9 x 53.3mm

- 0.43kg

- 147202-01

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 2

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

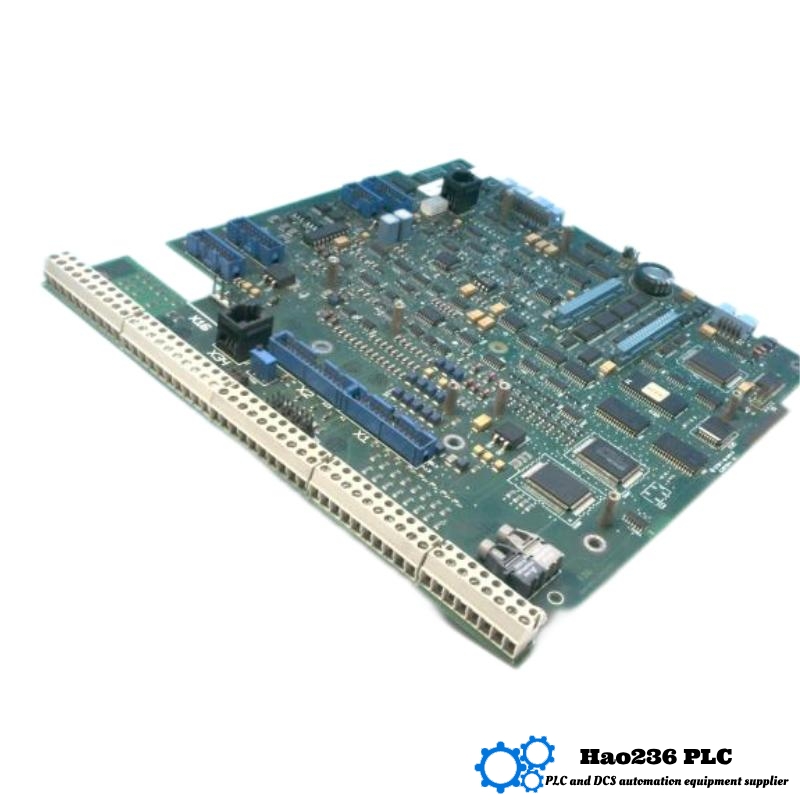

Bently Nevada 990-05-XX-03-05 Vibration Transmitter

Product Introduction

The Bently Nevada 990-05-XX-03-05 Vibration Transmitter is a part of Bently Nevada’s 990 Series, offering advanced vibration monitoring for rotating machinery. This high-performance device provides essential real-time data, enabling predictive maintenance and helping industries avoid costly downtime. The 990 series is designed for harsh environments, ensuring the reliable operation of critical equipment in various industrial settings.

With its rugged construction and precise measurements, the 990 vibration transmitter plays a vital role in detecting mechanical faults early. It supports industrial operations by alerting maintenance teams to potential issues before they escalate into expensive breakdowns.

Applications

The Bently Nevada 990-05-XX-03-05 Vibration Transmitter is widely used in industries that rely heavily on machinery performance, such as:

-

Power Generation: Ensures turbines, generators, and motors are operating efficiently and identifies potential issues early.

-

Oil & Gas: Monitors pumps, compressors, and other critical equipment in oil rigs, refineries, and processing plants.

-

Manufacturing: Tracks vibration levels in motors, conveyors, and heavy machinery to optimize operations.

-

Mining: Used in crushers, mills, and other high-impact machines to prevent sudden failures.

-

Water Treatment: Keeps pumps, motors, and compressors in check to maintain smooth water distribution and processing.

Product Advantages

-

Early Fault Detection: The device offers early warning signals for machinery issues, preventing sudden breakdowns.

-

Reliability: Built to last in demanding industrial environments with its durable, rugged design.

-

Ease of Integration: Easily integrates with existing control systems and condition monitoring setups.

-

Cost Efficiency: By detecting issues early, the transmitter reduces the likelihood of expensive emergency repairs and unscheduled downtime.

-

Compact Design: Despite its advanced features, the transmitter is compact and lightweight, allowing easy installation in tight spaces.

Brand Information

Bently Nevada, a subsidiary of Emerson, is renowned for producing high-quality condition monitoring solutions. The company has a long history of delivering reliable products for the industrial sector, with a strong focus on machinery protection, vibration monitoring, and diagnostic equipment. Bently Nevada’s products are trusted worldwide for their precision, durability, and innovative technologies that contribute to increasing operational efficiency and reducing maintenance costs.

Product Series

The 990 Series from Bently Nevada is known for its advanced vibration monitoring capabilities. These transmitters are specifically designed to enhance predictive maintenance programs. The 990 Series offers a variety of models for different vibration monitoring needs, ensuring accuracy and real-time alerts for machinery protection.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Bently Nevada 990-05-XX-03-05 |

| Vibration Measurement | Accelerometer-based |

| Output Type | 4-20 mA |

| Operating Temperature | -40°C to 85°C |

| Dimensions (L x W x H) | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Power Supply | 24V DC |

| Signal Processing | Analog signal conversion |

Related and Popular Models from the 990 Series

| Model | Vibration Measurement | Output Type | Operating Temperature | Dimensions | Weight |

|---|---|---|---|---|---|

| 990-05-70-01-05 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 100.1 x 73.9 x 53.3 mm | 0.43 kg |

| 990-05-70-02-00 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 100.1 x 73.9 x 53.3 mm | 0.43 kg |

| 990-05-70-01-06 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 98.0 x 70.0 x 52.0 mm | 0.45 kg |

| 990-05-70-01-07 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 102.0 x 75.0 x 55.0 mm | 0.47 kg |

| 990-05-70-02-02 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 105.0 x 76.0 x 54.0 mm | 0.49 kg |

Popular Bently Nevada Models (Across Other Series)

| Model | Vibration Measurement | Output Type | Operating Temperature | Dimensions | Weight |

|---|---|---|---|---|---|

| 330500-00-00 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 98.5 x 70.0 x 55.0 mm | 0.42 kg |

| 3300/03-01-00-02 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 95.0 x 69.0 x 50.0 mm | 0.40 kg |

| 3300/10-01-02-03 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 110.0 x 72.0 x 56.0 mm | 0.48 kg |

| 3300-10-01-00-02 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 105.0 x 70.0 x 54.0 mm | 0.45 kg |

| 3500/01-01-00-02 | Accelerometer-based | 4-20 mA | -40°C to 85°C | 98.0 x 68.0 x 53.0 mm | 0.43 kg |

FAQs for Bently Nevada 990-05-XX-03-05 Vibration Transmitter

Q1: What is the primary purpose of the Bently Nevada 990-05-XX-03-05 vibration transmitter?

A1: The primary purpose is to continuously monitor the vibration levels of rotating machinery, providing early warnings for potential mechanical issues to prevent unexpected downtime.

Q2: How does the transmitter detect vibration?

A2: The transmitter uses an accelerometer to measure vibrations, which are then converted into a 4-20 mA analog output signal for further analysis.

Q3: What industries can benefit from using the 990-05-XX-03-05 vibration transmitter?

A3: It is ideal for industries like power generation, oil & gas, manufacturing, mining, and water treatment, where monitoring rotating equipment is essential.

Q4: What is the power supply requirement for the 990-05-XX-03-05?

A4: The device requires a 24V DC power supply to operate.

Q5: Is the 990-05-XX-03-05 suitable for use in extreme environments?

A5: Yes, it is built to withstand harsh conditions, with an operating temperature range of -40°C to 85°C.

Q6: How is the vibration data transmitted?

A6: Vibration data is transmitted via a 4-20 mA analog output, which is compatible with most industrial control and monitoring systems.

Q7: What is the size of the Bently Nevada 990-05-XX-03-05 transmitter?

A7: The dimensions are 100.1 x 73.9 x 53.3 mm.

Q8: Can I integrate this transmitter with existing monitoring systems?

A8: Yes, the 990-05-XX-03-05 is compatible with various industrial control systems, making integration straightforward.

Q9: What is the weight of the Bently Nevada 990-05-XX-03-05?

A9: The weight is 0.43 kg, which makes it easy to install and integrate into your system.

Q10: How long does the 990-05-XX-03-05 last?

A10: The transmitter is designed for long-term use with minimal maintenance, providing many years of reliable service when properly installed and maintained.

Predictive Maintenance Starts Here

The Bently Nevada 990-05-XX-03-05 vibration transmitter helps you transition from reactive to predictive maintenance. Catch potential failures before they become costly downtime.

Maximize Equipment Longevity with Precision Monitoring

Extend the life of your rotating machinery with the Bently Nevada 990 vibration transmitter. Real-time data means you’ll never be caught off guard by sudden equipment failures.

Reliable Performance in Any Environment

Whether you’re operating in a power plant or on an offshore oil rig, the 990 vibration transmitter delivers real-time, accurate vibration data. Stay ahead of mechanical issues before they impact performance.

Protect Your Investment with Advanced Vibration Monitoring

Protect your machinery and your bottom line with the Bently Nevada 990-05-XX-03-05. Harness the power of predictive analytics for more efficient operations and fewer breakdowns.