ProductPRODUCT

Featured products

Contact Us

- Emerson

- A6312/06

- Mechanical Health Monitor

- USA

- 30 × 128.4 x 160 mm

- 0.32 kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 19

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

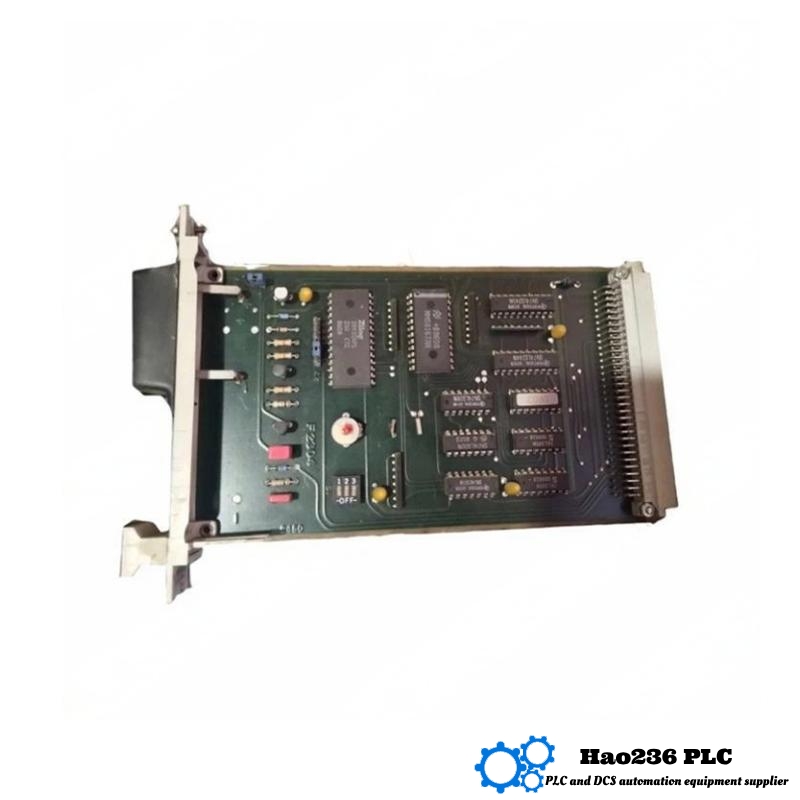

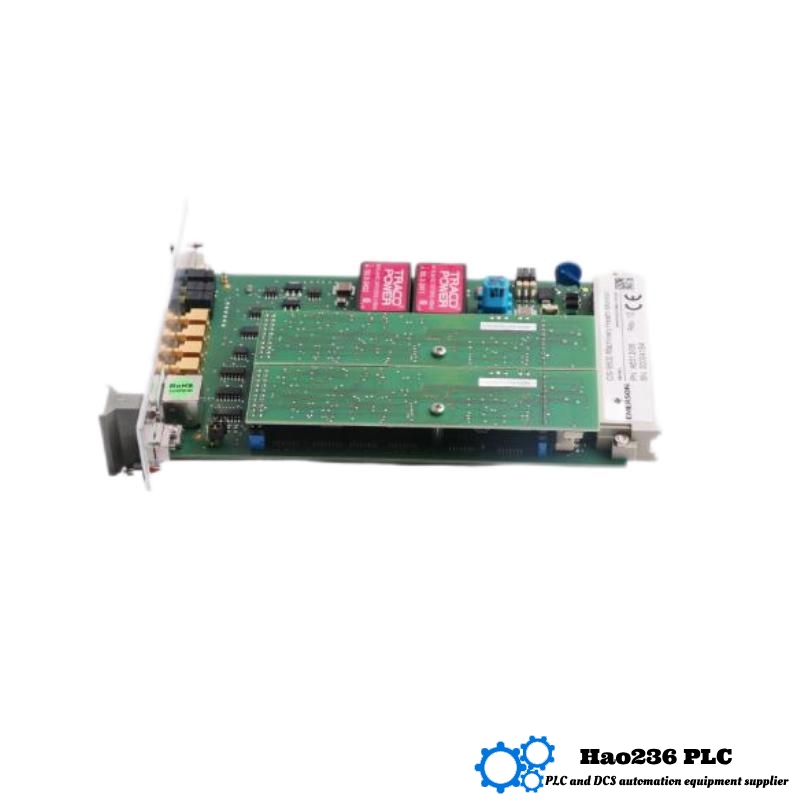

Emerson A6312/06 Mechanical Health Monitor

Product Overview:

The Emerson A6312/06 is a part of the CSI 6500 series, designed as a high-performance mechanical health monitor for critical rotating machinery. This advanced device provides real-time condition monitoring by assessing vibration and temperature, ensuring early detection of faults and preventing costly breakdowns. The A6312/06 is ideal for industries such as oil and gas, power generation, and manufacturing, offering a reliable and cost-effective solution for machinery health management.

Product Features:

- Real-Time Monitoring: The A6312/06 continuously tracks vibration and temperature levels to monitor machinery health.

- Early Fault Detection: Detects abnormalities such as misalignment, imbalance, and wear, providing actionable insights to prevent failures.

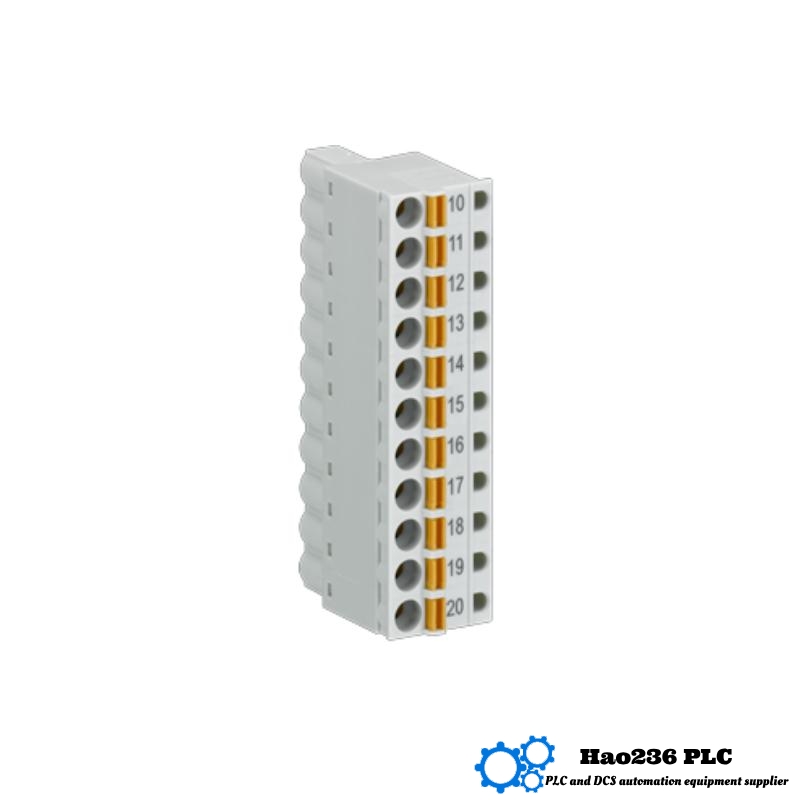

- Compact Design: With dimensions of 30 x 128.4 x 160 mm and weighing only 0.32 kg, the A6312/06 can be easily integrated into tight spaces without sacrificing performance.

- Multiple Communication Protocols: It supports Ethernet, Modbus TCP, and RS-485, offering flexible connectivity and easy integration into your existing network.

- Flexible Installation: The unit supports both panel mount and DIN rail installation, offering versatility in various industrial environments.

- Energy Efficient: Operating on 24 VDC, the A6312/06 is designed to minimize energy consumption while maintaining continuous operation.

Applications:

The Emerson A6312/06 mechanical health monitor is specifically suited for a variety of industries, including:

- Oil and Gas: Monitors compressors, pumps, and turbines, ensuring continuous and safe operations in harsh environments.

- Power Generation: Helps maintain critical equipment like turbines and generators in power plants, optimizing operational efficiency and uptime.

- Manufacturing: Suitable for monitoring motors, conveyor belts, and other machinery in industrial production lines.

- Water Treatment: Protects pumps and motors in water treatment facilities by continuously monitoring their condition.

- Mining: Tracks heavy machinery like crushers and mills, ensuring optimal performance and reducing the risk of costly downtime.

Advantages:

- Proactive Maintenance: By detecting faults early, the A6312/06 helps to prevent unplanned downtime, leading to substantial savings in maintenance costs.

- Extended Equipment Lifespan: Continuous monitoring ensures that equipment runs at optimal performance, extending its service life and reducing the need for costly repairs.

- Cost-Effective Solution: With its ability to detect potential issues early, the A6312/06 reduces the need for expensive reactive maintenance and repairs.

- Seamless Integration: The A6312/06 supports a wide range of communication protocols, making it easy to integrate into existing control systems and infrastructure.

- Durability: Designed for use in harsh industrial environments, the A6312/06 ensures reliable performance even in challenging conditions.

Brand: Emerson

Emerson is a global leader in process automation, providing innovative and cutting-edge solutions to industries worldwide. The company’s products, including the A6312/06, are trusted for their durability, efficiency, and performance in a variety of industrial applications.

Product Series: CSI 6500 Series

The CSI 6500 series is a comprehensive range of mechanical health monitoring solutions that provide continuous monitoring for vibration and temperature. This series is designed for industries that rely on critical rotating machinery, helping to optimize maintenance practices and prevent unexpected failures.

Technical Specifications:

| Parameter | Value |

|---|---|

| Model Number | A6312/06 |

| Dimensions (H x W x D) | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Vibration Monitoring | Yes |

| Temperature Monitoring | Yes |

| Communication Interface | Ethernet, Modbus TCP, RS-485 |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -20°C to +85°C |

| Power Supply | 24 VDC |

| Mounting Type | Panel Mount, DIN Rail |

Recommended Models in the CSI 6500 Series

| Model Number | Description | Key Features |

|---|---|---|

| CSI 6200 | Single-channel vibration and temperature monitor | Compact design for small machinery |

| CSI 6400 | Multi-channel vibration and temperature monitor | Ideal for large, complex systems |

| CSI 6600 | Wireless vibration and temperature monitor | Real-time diagnostics with remote access |

| CSI 6700 | Cloud-enabled condition monitoring system | Integrated cloud analytics and data storage |

| CSI 6900 | Advanced multi-point condition monitoring | Monitors multiple points across machinery |

Popular Emerson Models

| Model Number | Description | Key Features |

|---|---|---|

| Roxar 2600 | Subsea condition monitoring system | Designed for offshore and subsea environments |

| MX6 | Multi-gas detection system | Portable, with high precision and real-time analytics |

| SensiTouch | Smart sensor interface with touchscreen | Easy to use, providing real-time data |

| X-Stream | High-speed process automation system | Optimizes and automates industrial processes |

| FlexFlow | Advanced flow measurement system | Accurate and reliable flow measurement |

FAQ for Emerson A6312/06 Mechanical Health Monitor

Q1: What does the A6312/06 monitor?

A1: The A6312/06 monitors vibration and temperature to assess the health of critical rotating machinery.

Q2: What is the power supply requirement for the A6312/06?

A2: The A6312/06 operates on a 24 VDC power supply.

Q3: How does the A6312/06 integrate with existing systems?

A3: The A6312/06 supports Ethernet, Modbus TCP, and RS-485, allowing easy integration into existing systems.

Q4: What is the size of the A6312/06?

A4: The A6312/06 measures 30 x 128.4 x 160 mm and weighs 0.32 kg.

Q5: Is the A6312/06 suitable for outdoor environments?

A5: The A6312/06 is designed for indoor use with an operating temperature range of -10°C to +60°C.

Q6: How does the A6312/06 help reduce downtime?

A6: The A6312/06 detects early signs of faults, allowing for early maintenance intervention and reducing unexpected downtime.

Q7: What is the recommended installation method for the A6312/06?

A7: The A6312/06 can be installed using panel mounting or DIN rail for flexibility in installation.

Q8: Can the A6312/06 be used in harsh environments?

A8: Yes, the A6312/06 is designed to operate reliably in tough industrial conditions.

Q9: Is the A6312/06 easy to install?

A9: Yes, the A6312/06 is designed for easy installation with flexible mounting options.

Q10: Does the A6312/06 provide real-time diagnostics?

A10: Yes, the A6312/06 provides real-time monitoring and diagnostics, offering immediate feedback on equipment health.

Stay Ahead of Equipment Failures

With the Emerson A6312/06, proactively monitor your rotating machinery and detect faults before they disrupt operations.

Prevent Downtime, Maximize Performance

Enhance the reliability of your equipment with continuous monitoring by the A6312/06. Reduce maintenance costs and extend asset life.

Precision Monitoring for Critical Machinery

The Emerson A6312/06 offers precise vibration and temperature monitoring, ensuring the health of your most vital equipment.

Get Ahead with Real-Time Diagnostics

The A6312/06 provides real-time insights into equipment health, enabling informed decision-making and optimized maintenance schedules.