ProductPRODUCT

Featured products

Contact Us

- Emerson

- A6410

- Valve and Shell Expansion Monitor

- USA

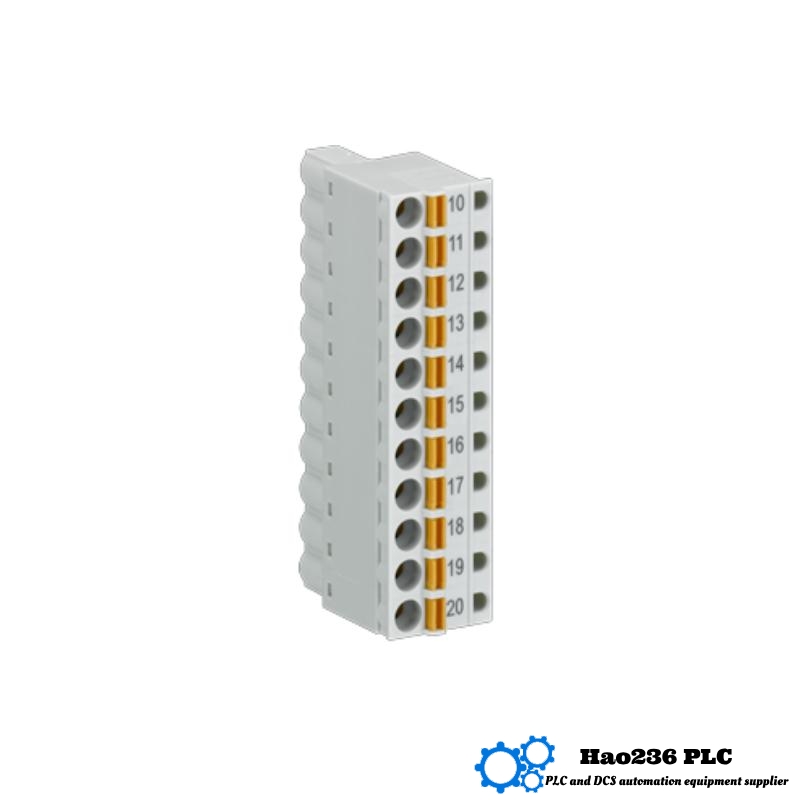

- 160 x 128.4 x 30 mm

- 0.32 kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 12

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Introduction

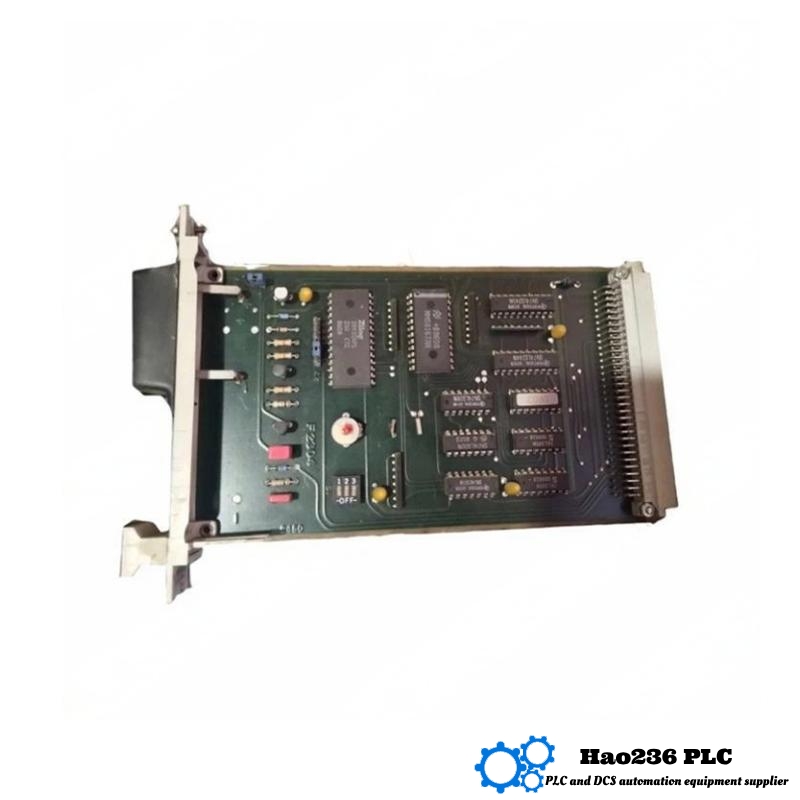

The Emerson A6410 is a Valve and Shell Expansion Monitor designed to provide continuous monitoring of valve and shell expansion in industrial systems. It is part of the AMS 6500 series and is engineered to protect critical valves, pipelines, and equipment by detecting any excessive thermal or mechanical expansion. These conditions can lead to system malfunctions or even catastrophic failure if left unmonitored.

The A6410 uses advanced sensors and algorithms to measure expansion, helping operators prevent issues before they escalate. This makes the device essential for industries where the integrity of valves, pipes, and shells are crucial, including the oil and gas, chemical, and power generation sectors.

Product Applications

The A6410 is widely used in the following applications:

- Oil and Gas: Detects thermal expansion in pipelines and valves to prevent leaks, ruptures, and other failures in high-pressure environments.

- Power Generation: Monitors the expansion of steam and gas turbines, along with the associated valves, to avoid damage during operation.

- Chemical Processing: Protects critical equipment from thermal stresses that could compromise the safety of chemical reactors and pipelines.

- Manufacturing: Ensures the smooth operation of production lines that involve high temperatures and pressures, such as those in the automotive or steel industries.

- Marine: Used for monitoring the expansion of hulls and engine components, ensuring the safety and reliability of marine vessels.

Product Advantages

- Early Detection of Thermal Expansion: The A6410 offers early detection of expansion in valves and shells, allowing corrective actions to be taken before damage occurs.

- Reliability in Harsh Environments: Built to withstand challenging industrial environments, the A6410 offers superior durability in applications that involve extreme temperatures and pressures.

- Easy Integration: The monitor can be easily integrated into existing control systems and can communicate through standard protocols like Modbus.

- Prevents Equipment Damage: By detecting expansion anomalies, it helps prevent costly repairs and downtime by mitigating risks associated with valve and shell failure.

- Advanced Sensor Technology: The A6410 uses high-precision sensors for accurate measurements, ensuring reliable protection across various industrial applications.

Brand and Series Information

- Brand: Emerson

- Series: AMS 6500 Series

Product Specifications

| Parameter | Description |

|---|---|

| Model | A6410 |

| Type | Valve and Shell Expansion Monitor |

| Size | 160 x 128.4 x 30 mm |

| Weight | 0.32 kg |

| Input | Temperature and displacement sensors |

| Output | Analog (4-20 mA), Digital (Modbus) |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 24 V DC |

| Communication | Modbus, 4-20 mA analog output |

| Response Time | < 1 second for detection of abnormal expansion |

| Accuracy | ±0.1% of full scale |

| Mounting | Panel-mountable, easy integration with existing systems |

Related Models in the Same Series (AMS 6500)

Below are five related models in the AMS 6500 series:

| Model | Description | Key Parameters |

|---|---|---|

| A6500 | Core monitoring device for machinery and pipeline protection | 4-20 mA output, Modbus, Vibration and temperature monitoring |

| A6510 | Advanced expansion monitor for steam turbines | Dual input channels, Temperature and displacement sensors |

| A6520 | Shell expansion monitor for high-pressure systems | Panel-mountable, Dual relay output, Modbus communication |

| A6530 | Temperature and pressure monitoring for valve systems | 24 V DC, Real-time monitoring, Digital outputs |

| A6540 | Integrated solution for rotating machinery expansion monitoring | 4-20 mA, Integrated diagnostics, Response time < 1 second |

5 Popular Models from Emerson

| Model | Description | Key Parameters |

|---|---|---|

| A2100 | High-accuracy vibration monitor for rotating equipment | 4-20 mA, Digital outputs, Real-time diagnostics |

| A2500 | Machinery protection relay for industrial equipment | Dual input channels, Temperature and pressure sensors |

| A3300 | Motor protection relay for large industrial motors | High-speed response, Alarm configuration |

| A5000 | Process and environmental monitoring for chemical plants | Multi-sensor input, Real-time data logging |

| A5300 | Real-time temperature and pressure monitoring for valve systems | 4-20 mA output, Modbus communication, Adjustable alarm settings |

FAQs

-

Q: What is the primary function of the A6410 valve and shell expansion monitor?

A: The A6410 detects thermal expansion and displacement in valves and shells to prevent damage from excessive thermal or mechanical stresses. -

Q: What industries benefit from using the A6410?

A: The A6410 is ideal for industries like oil and gas, power generation, chemical processing, manufacturing, and marine operations. -

Q: How does the A6410 monitor expansion?

A: It uses temperature and displacement sensors to measure the expansion of equipment and detects any abnormal changes in size. -

Q: What is the power supply requirement for the A6410?

A: The A6410 operates with a 24 V DC power supply. -

Q: Can the A6410 be integrated with other systems?

A: Yes, the A6410 is designed for easy integration with existing control systems via Modbus or 4-20 mA output. -

Q: What is the response time of the A6410?

A: The A6410 has a response time of less than 1 second to detect expansion anomalies. -

Q: What is the size and weight of the A6410?

A: The A6410 has dimensions of 160 x 128.4 x 30 mm and weighs 0.32 kg. -

Q: Does the A6410 provide real-time monitoring?

A: Yes, the A6410 offers continuous real-time monitoring of valve and shell expansion. -

Q: How accurate is the A6410 in detecting expansion?

A: The A6410 has an accuracy of ±0.1% of the full scale, ensuring precise and reliable measurements. -

Q: What outputs does the A6410 provide?

A: The A6410 provides 4-20 mA analog output and digital Modbus communication for easy integration and alarm management.

Protect Your Valves and Shells with Emerson’s A6410

The A6410 Valve and Shell Expansion Monitor provides critical protection by detecting expansion anomalies in real time, preventing costly damage and downtime.

Emerson A6410: Ensuring the Integrity of Your Equipment

With Emerson’s A6410, you can trust that your valves and shells are protected from thermal expansion, keeping your operations running smoothly and safely.

Prevent Damage with Emerson’s A6410 Expansion Monitoring Solution

The A6410 is the ultimate solution for preventing damage caused by excessive thermal expansion in critical valve and shell systems. Reliable, accurate, and built for tough environments.

Real-Time Expansion Monitoring with Emerson A6410

Protect your industrial systems from costly failures with the Emerson A6410, designed to provide fast, accurate detection of expansion in high-pressure and high-temperature applications.