ProductPRODUCT

Featured products

Contact Us

- Invensys Triconex

- 8101

- Expansion Chassis

- USA

- 483 x 578 x 451mm

- 19.7kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 7

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8613620394314 | ||

| +8613620394314 | |||

| 13620394314 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Triconex 8101 Expansion Chassis

Product Introduction

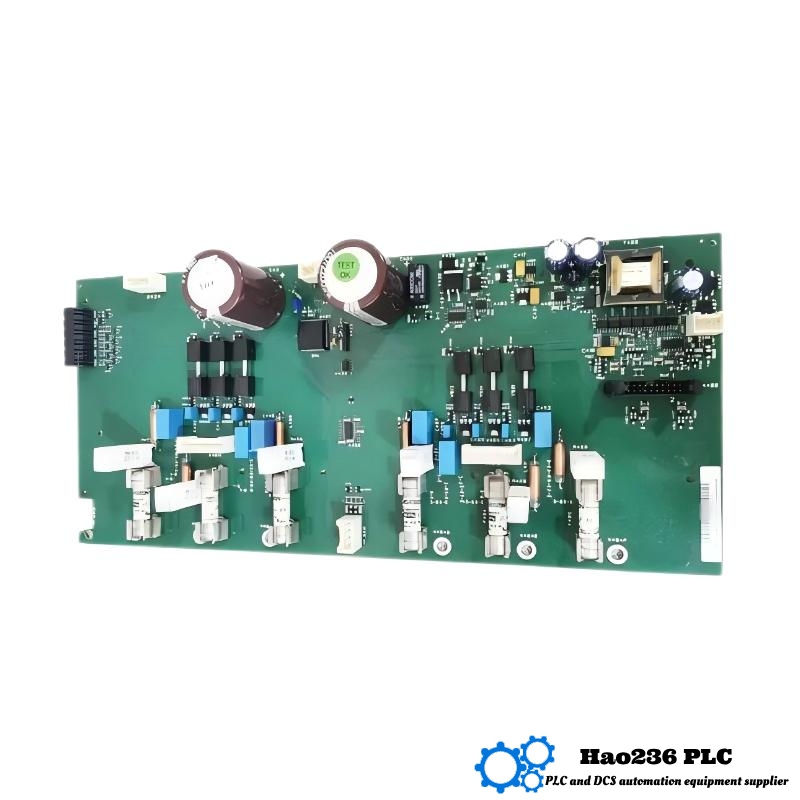

The Triconex 8101 is a robust and highly reliable expansion chassis designed for critical control and safety system applications. As part of the Triconex safety platform, the 8101 chassis is used to expand the I/O capabilities of a Tricon system. It enables users to connect additional I/O modules in large or distributed control architectures while maintaining the highest standards of system availability and fault tolerance.

Engineered for use in the most demanding environments, the 8101 supports mission-critical operations where safety, performance, and scalability are non-negotiable. It is a cornerstone in industries that demand SIL 3-certified systems, including power generation, refining, chemicals, and nuclear energy sectors.

Applications

-

Petrochemical Plants: Extending I/O capabilities in ESD (Emergency Shutdown) systems and Burner Management Systems (BMS).

-

Power Generation: Integrating additional turbine or generator control modules into centralized DCS platforms.

-

Oil & Gas: Wellhead safety systems, compressor controls, and HIPPS (High Integrity Pressure Protection Systems).

-

Pharmaceutical Industry: Supporting validated safety systems for cleanrooms and batch processing lines.

-

Nuclear Facilities: Applied in reactor safety, monitoring, and critical logic handling.

Advantages

-

SIL 3 Certified: Provides the utmost in safety integrity, compliant with IEC 61508 standards.

-

High Channel Density: Maximizes expansion capacity while minimizing footprint.

-

Redundancy-Ready: Supports fault-tolerant triple modular redundancy (TMR).

-

Rugged Construction: Industrial-grade design ensures long-term operation in harsh conditions.

-

Seamless Integration: Fully compatible with the Tricon system’s main chassis and Triconex software tools.

Brand and Series

-

Brand: Triconex (a Schneider Electric company)

-

System Compatibility: Tricon and Triconex Safety Instrumented Systems (SIS)

Product Parameters

| Parameter | Value |

|---|---|

| Model | Triconex 8101 |

| Type | Expansion Chassis |

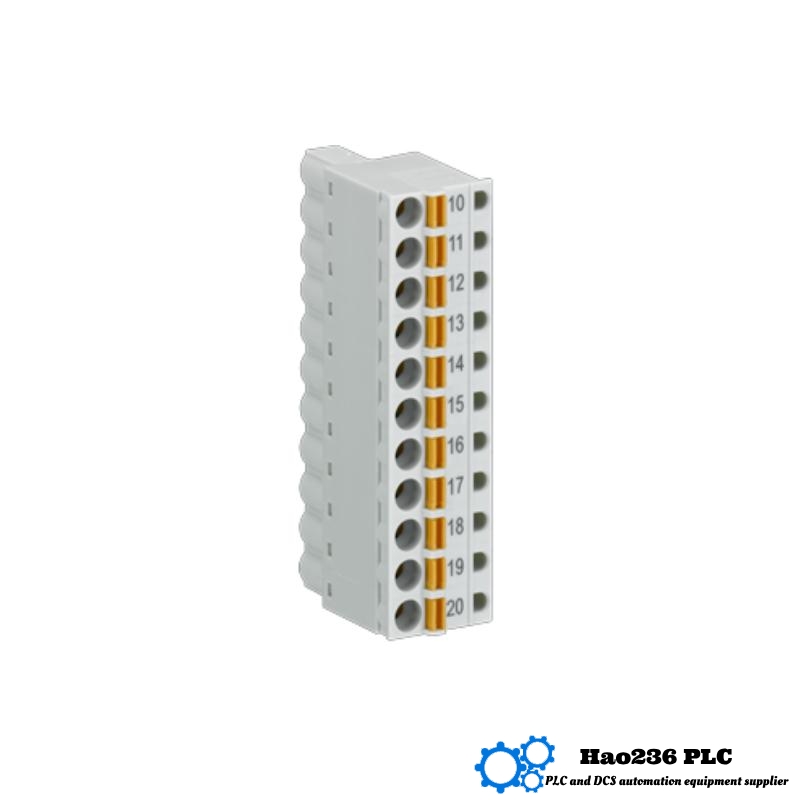

| Slots | 18 slots |

| Power Supply Compatibility | Dual redundant power supplies |

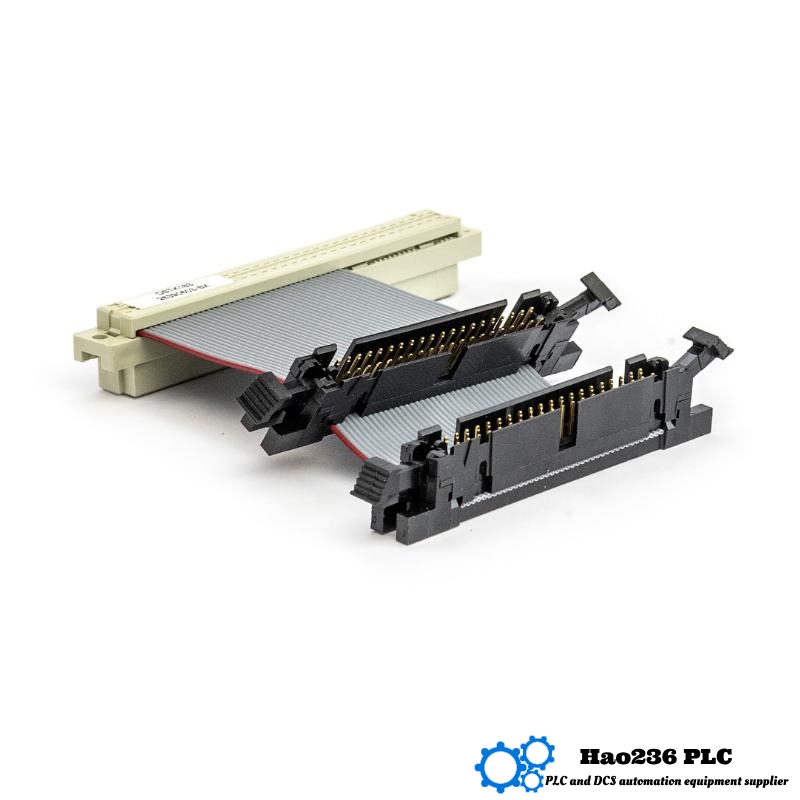

| Bus Type | Tricon Communication Bus (TCB) |

| Mounting Type | Rack Mount |

| Dimensions | 483 x 578 x 451 mm |

| Weight | 19.7 kg |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Certifications | CE, ATEX, SIL 3 (IEC 61508), CSA |

| Material | Anodized Aluminum Frame |

Related or Same Series Models

| Model | Description | Dimensions (mm) | Weight |

|---|---|---|---|

| 8110 | Main Processor Chassis | 483 x 578 x 451 | 19.8 kg |

| 8120 | Remote Expansion Chassis | 483 x 578 x 451 | 20.0 kg |

| 8311 | I/O Base Chassis with Redundancy Support | 483 x 578 x 451 | 19.5 kg |

| 8200 | Power Supply Chassis | 483 x 200 x 400 | 12.5 kg |

| 8401 | Diagnostic Chassis | 483 x 300 x 450 | 14.2 kg |

Popular Triconex Models

| Model | Description | Type | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 3008 | Tricon Main Processor | CPU | 483 x 578 x 451 | 20.5 kg |

| 3700A | Digital Output Module | I/O Module | 200 x 100 x 40 | 0.95 kg |

| 3503E | Analog Input Module (HART) | I/O Module | 200 x 100 x 40 | 0.93 kg |

| 3625 | Digital Input Module | I/O Module | 200 x 100 x 40 | 0.91 kg |

| 4351B | Enhanced Main Processor | CPU | 483 x 578 x 451 | 21.0 kg |

FAQ – Triconex 8101 Expansion Chassis

Q1: What is the main function of the Triconex 8101?

A1: It serves as an expansion chassis to increase the I/O capacity of a Triconex safety control system.

Q2: How many modules can the 8101 accommodate?

A2: It can house up to 18 modules in a single chassis.

Q3: Is the 8101 compatible with Tricon main processors?

A3: Yes, it’s fully compatible with Tricon and Triconex processor modules like the 3008 or 4351B.

Q4: Can I install power supply modules directly into the 8101?

A4: No, power supplies are typically managed through dedicated units like the 8200, but the 8101 supports redundant power input.

Q5: Does the chassis support hot-swapping of modules?

A5: Yes, the system architecture allows for certain modules to be replaced while the system remains in operation.

Q6: What type of system architecture does it use?

A6: It uses a Triple Modular Redundancy (TMR) system to ensure fail-safe performance.

Q7: Is this chassis suitable for hazardous areas?

A7: Yes, it carries certifications such as ATEX and CE for use in hazardous environments.

Q8: How is the communication handled between this and the main chassis?

A8: It uses a dedicated Tricon Communication Bus (TCB) for fast and secure data exchange.

Q9: Can it be wall-mounted or does it require a rack?

A9: The 8101 is designed for rack mounting due to its size and modular structure.

Q10: What tools are used for configuring systems that include the 8101?

A10: Triconex programming and diagnostic tools like TriStation 1131 are typically used.

Expand Without Limits

Empower your Triconex system with the 8101 Expansion Chassis – built for scalable safety and reliable performance.

Future-Proof Your Safety Infrastructure

The Triconex 8101 gives your control systems room to grow with secure and certified expansion.

Industrial Safety Meets Modular Scalability

From oil platforms to nuclear reactors, the 8101 ensures your safety system expands without compromise.

Built for Critical Environments

Heavy-duty, high-capacity, and safety-certified – the Triconex 8101 is your foundation for control system growth.